Instrument category

The pharmaceutical industry has extremely high requirements for the cleanliness of the production environment and product quality. Therefore, it is necessary to use a variety of instruments equipped with filters to ensure the purity and safety of drug production.

High-efficiency filter leak detection system: In the pharmaceutical industry, the production of drugs has extremely high requirements for environmental hygiene. Even tiny particles and microorganisms in the air may affect product quality. The high-efficiency filter leak detection system is used for air purification in the production and filling processes of pharmaceuticals to ensure that the environment and product quality meet the standards.

Centrifuge: It separates suspended solids from liquids through rotation and is an essential filtration method for many pharmaceutical companies. It can handle samples of various sizes, ranging from small laboratory applications to large-scale industrial production.

Columnar adsorption material equipment: Utilizing adsorption materials to separate target molecules from mixtures is a common and effective method, widely used in fields such as protein purification.

Thin-layer chromatography equipment: It involves coating a fine layer structure on a flat surface and then using a solvent to move to separate and locate the sample components. It is very useful for rapid detection of whether a sample contains a specific chemical substance.

Microporous membrane sieve: It is used to remove small particles, cells or other impurities larger than a certain size. In the pharmaceutical industry, high-efficiency microporous membrane sieves are particularly crucial as they can maintain high purity while reducing operation time.

Ultrasonic cleaning system: It releases the dirt deposited on the container walls by generating intense vibrations. The cleaned containers can be reused for precise measurement and mixing of reactants.

The three-in-one filter (MY series integrated filter, washing and drying machine) : It integrates functions such as filtration, washing and drying into one machine and is widely used in the pharmaceutical industry. It features repeatable multiple pulping and filtration, CIP in-place cleaning, SIP in-place sterilization, and full-process automated program control. It is suitable for multiple fields such as antibiotic production, raw material drug purification, plant extract processing, vitamin preparation, bacterial residue filtration and washing, and fragrance preparation.

Fully automatic filter integrity tester: It is suitable for the integrity testing of sterilization-grade filter elements in the production processes of injections, sterile raw materials, etc., ensuring that the drug production process is pollution-free. This instrument supports five mainstream detection modes, including bubble point, forward flow (diffusion flow), water intrusion, and pressure holding. It can provide non-destructive testing services for different materials and specifications of filter components such as pleated filter cartridges, stacked filter cartridges, and flat filter membranes.

Zhehan offers filtration solutions for instruments in the pharmaceutical industry, helping you reduce production costs and improve product quality.

-

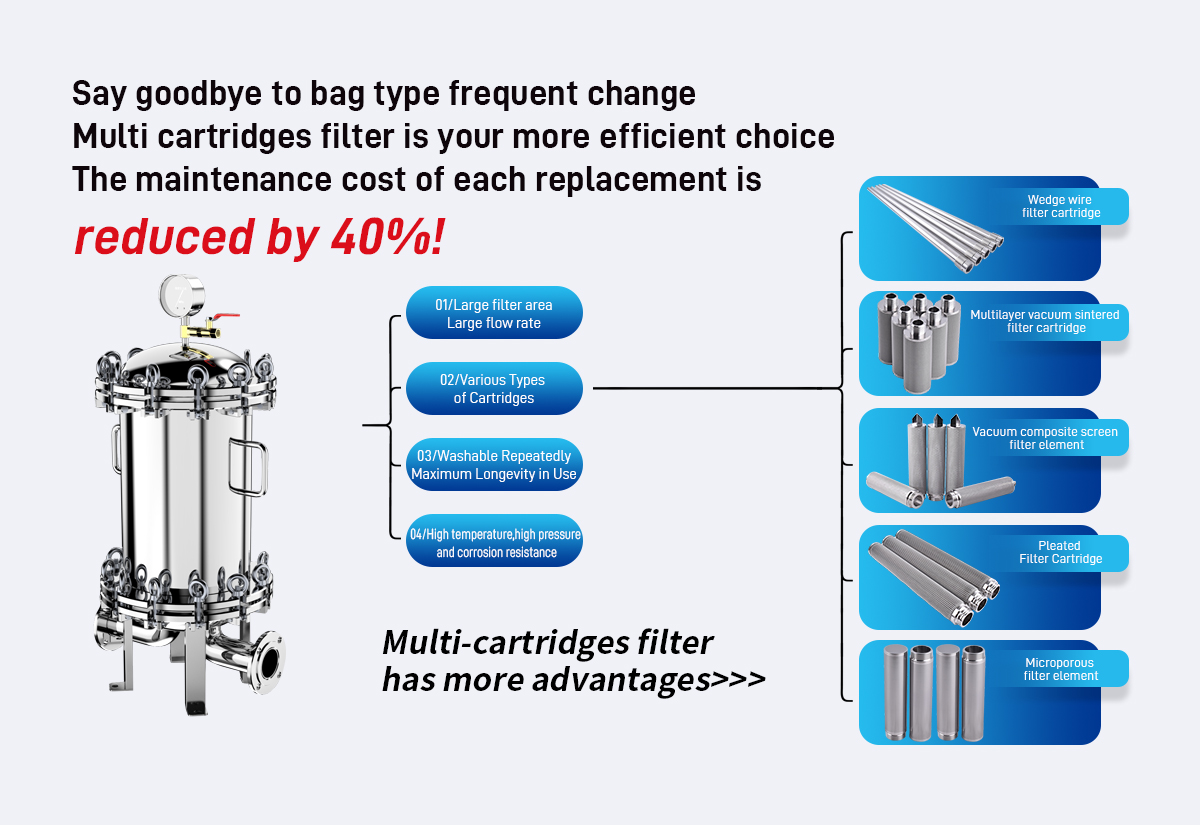

Multi-core filter

-

Stainless steel multi-bag filter

-

Online filter (external scraper

-

Dynamic self-cleaning filter

-

Stainless steel gas filter

-

Stainless steel respirator

-

Stainless steel Y-type angled filter

-

Stainless steel Y-type filter

-

Stainless steel Y-type filter

-

Straight-through pipe filter

-

Stainless steel magnetic filter

-

Stainless steel wedge-shaped wire filter element

-

Stainless steel pleated mesh filter element

-

Stainless steel microporous filter element

-

Stainless steel plate mesh filter element

-

Stainless steel composite mesh filter element