- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

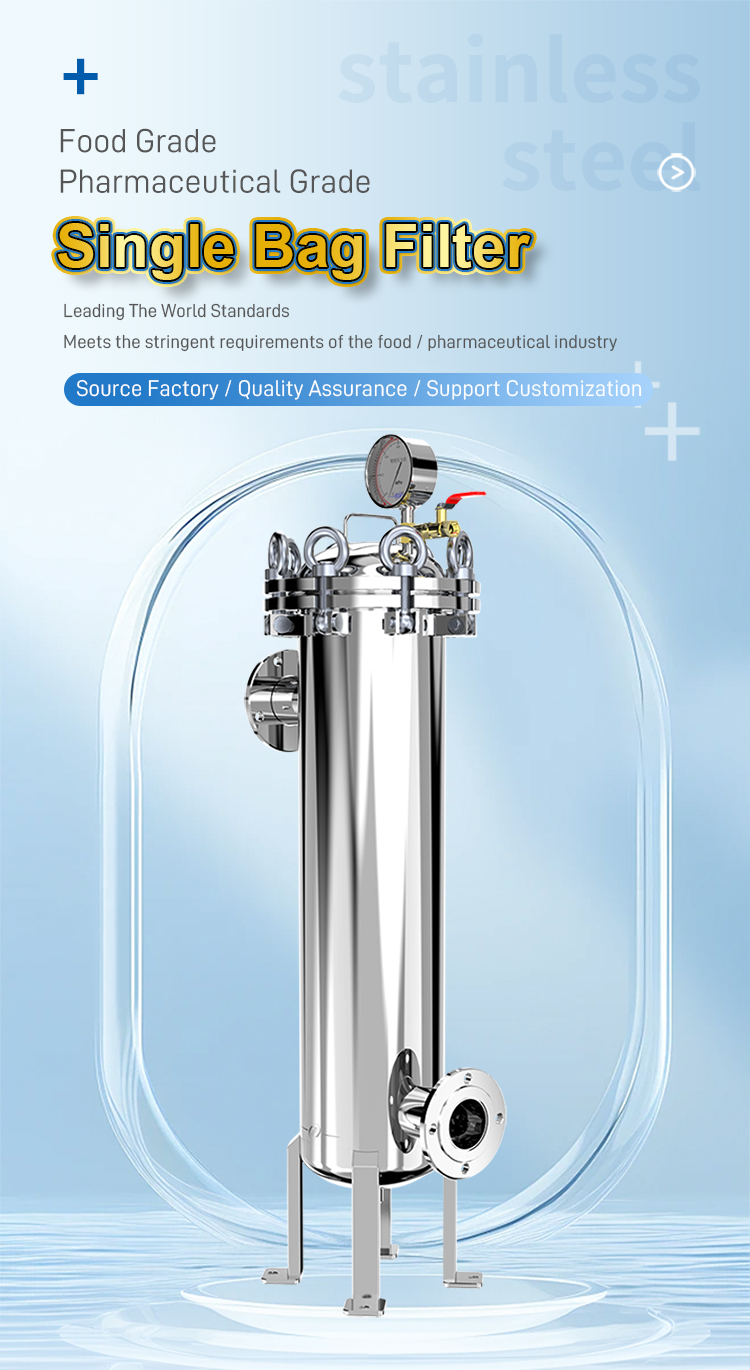

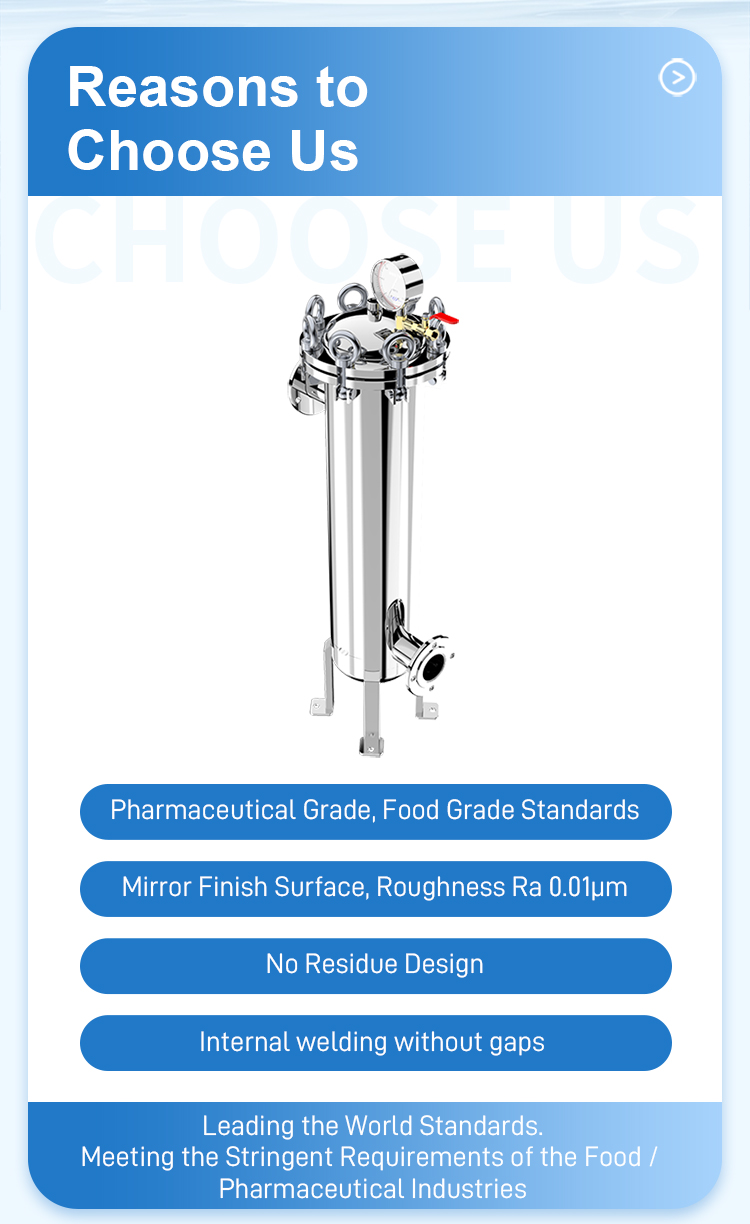

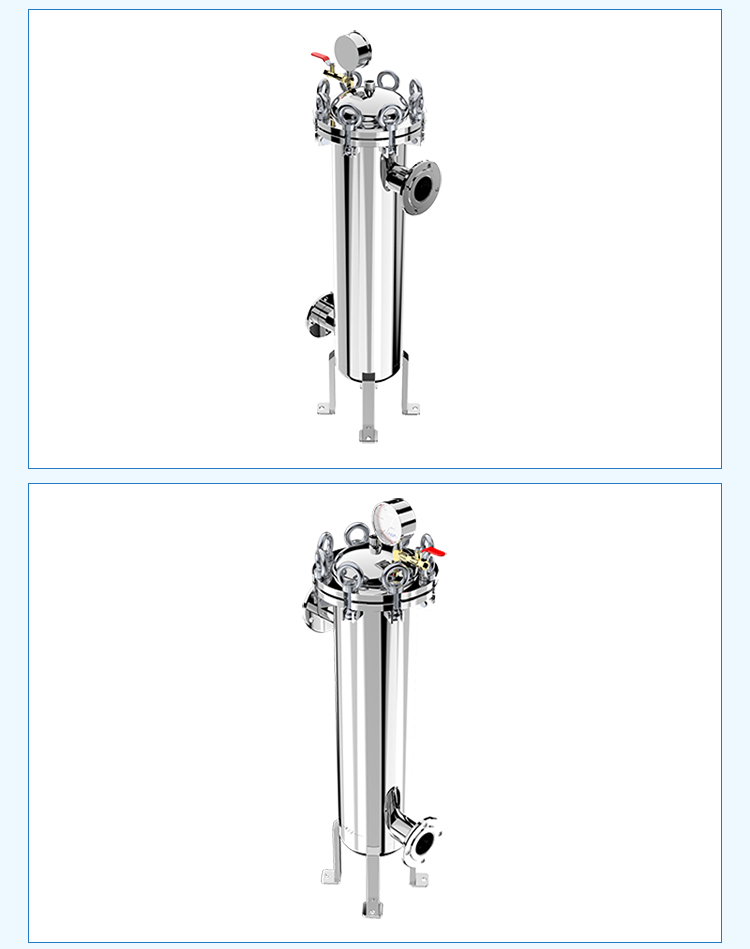

The stainless steel single-bag filter is a new type of filtration system. Inside, the liquid filter bag is supported by a perforated plate mesh basket. The liquid flows in from the water inlet, passes through the filter bag for filtration and then flows out. Impurities are intercepted in the filter bag, which can be replaced or cleaned.

Features

Structure and operation: Compact structure, reasonable size, simple and convenient installation and operation, and small floor space. It adopts a top opening structure, which is convenient for operation and filter bag replacement, saving time and labor costs. The probability of side leakage of the filter bag is low, which can ensure the filtration quality. The filter machine requires no cleaning. The replacement of filter bags can be completed within 30 seconds, saving labor and time.

Filtration performance: High filtration accuracy, suitable for any fine particles or suspended matter, with a filtration range from 0.5 to 200 microns. The processing flow rate per unit filtration area is relatively large, the filtration resistance is low, and the filtration efficiency is high. The filtration function of one liquid filter bag is equivalent to 5 to 10 times that of a filter element, which can significantly reduce costs.

Material characteristics: Made of stainless steel materials such as SUS304, SUS316, and SUS316L, it features excellent corrosion resistance and high-temperature resistance, and is suitable for filtration of various media.

Diverse specifications: including low-pressure type, side-entry type, top-entry type, multi-bag type, horizontal type and other different types, which can meet the filtration requirements of different flow rates.

"Application

Chemical industry: Effectively remove impurities and suspended solids from solutions, ensuring the stability and purity of chemicals, used in lubricating oil filtration, catalyst recovery, oil slurry separation, etc.

Pharmaceutical industry: In the process of drug production, it ensures the safety and efficacy of drugs and is widely applied in the purification of active pharmaceutical ingredients, clarification of preparations, and treatment of process water, etc.

Food and beverage industry: Remove foreign substances and insoluble particles from products to ensure consumer health. For instance, in the production processes of fruit juice, alcohol, edible oil, etc., remove impurities such as fruit pulp fibers, yeast, and protein precipitates from raw materials.

Water treatment and environmental protection industry: It is applicable to fields such as industrial water filtration, sewage treatment, and drinking water purification. It can remove suspended solids, rust, etc. from circulating cooling water and cleaning water. In sewage treatment, it serves as a pretreatment or advanced treatment unit to remove suspended solids, oils, and other pollutants.

Electronics industry: In the process of preparing ultrapure water, it serves as a pre-filtration or terminal filtration stage to ensure that the water quality meets strict requirements for conductivity and particle count. It is suitable for the preparation of ultrapure water in semiconductor, flat panel display and other industries.