- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

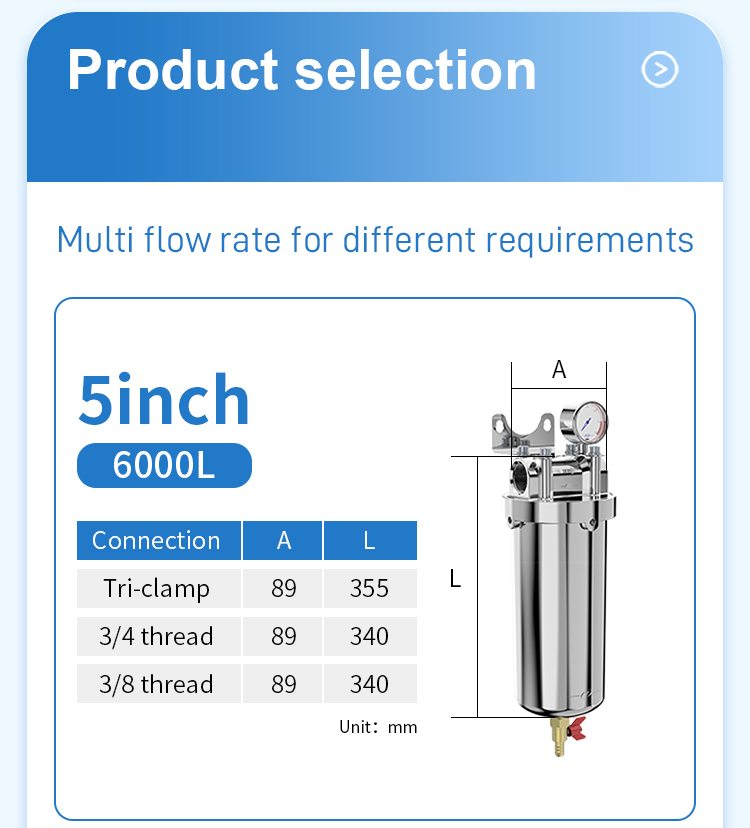

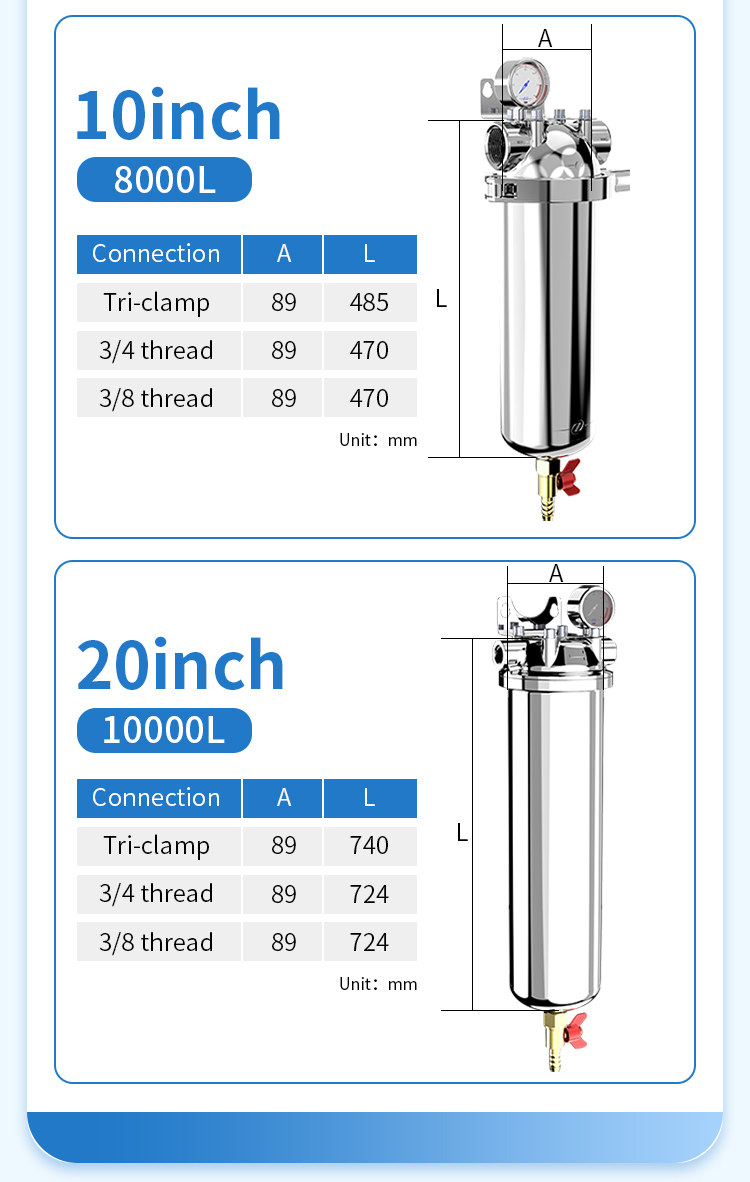

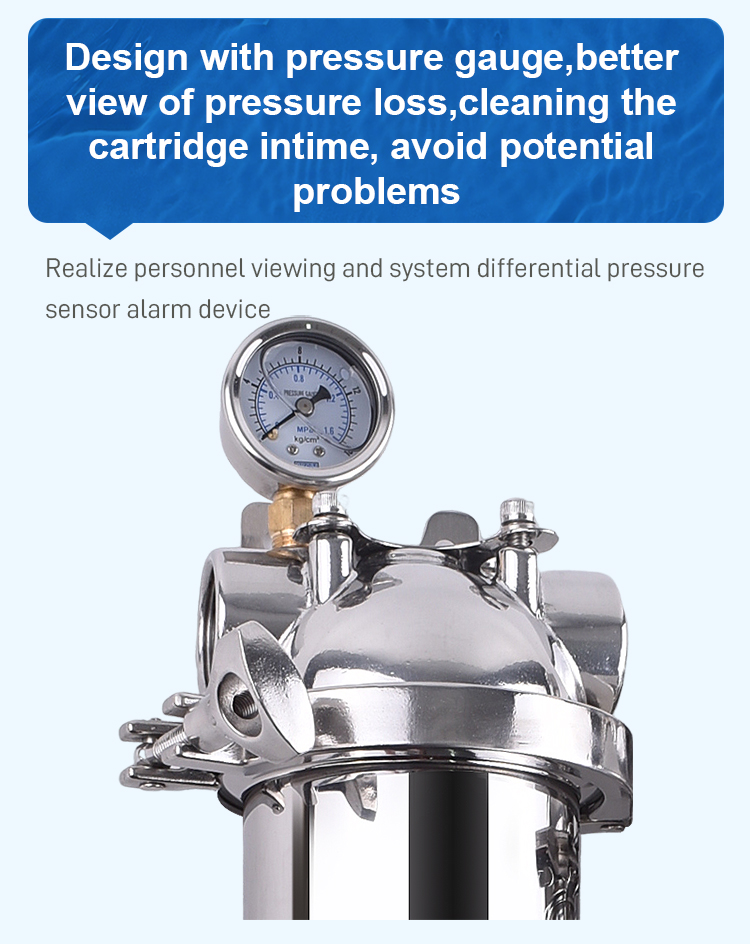

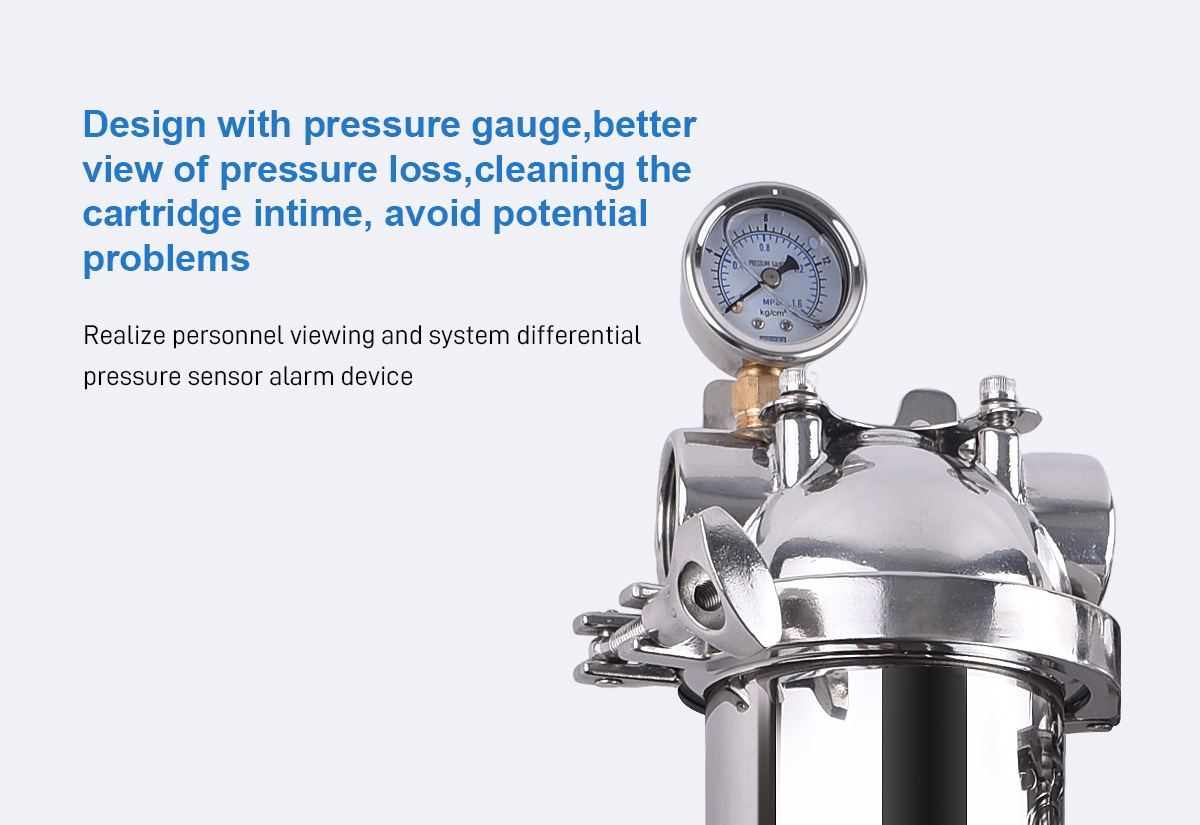

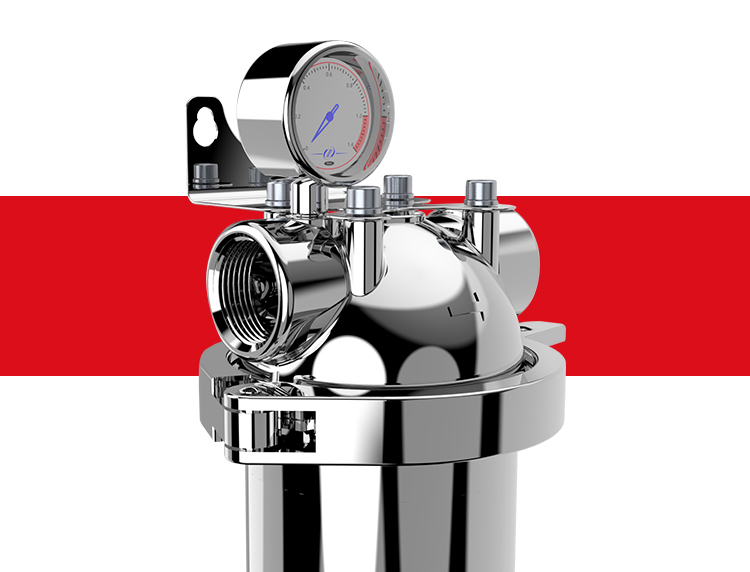

Stainless steel industrial pre-filters are installed at the front end of industrial pipelines to conduct preliminary filtration of fluids. They can effectively remove suspended particles, impurities, etc. from the fluids, protecting the normal operation of downstream equipment.

Features

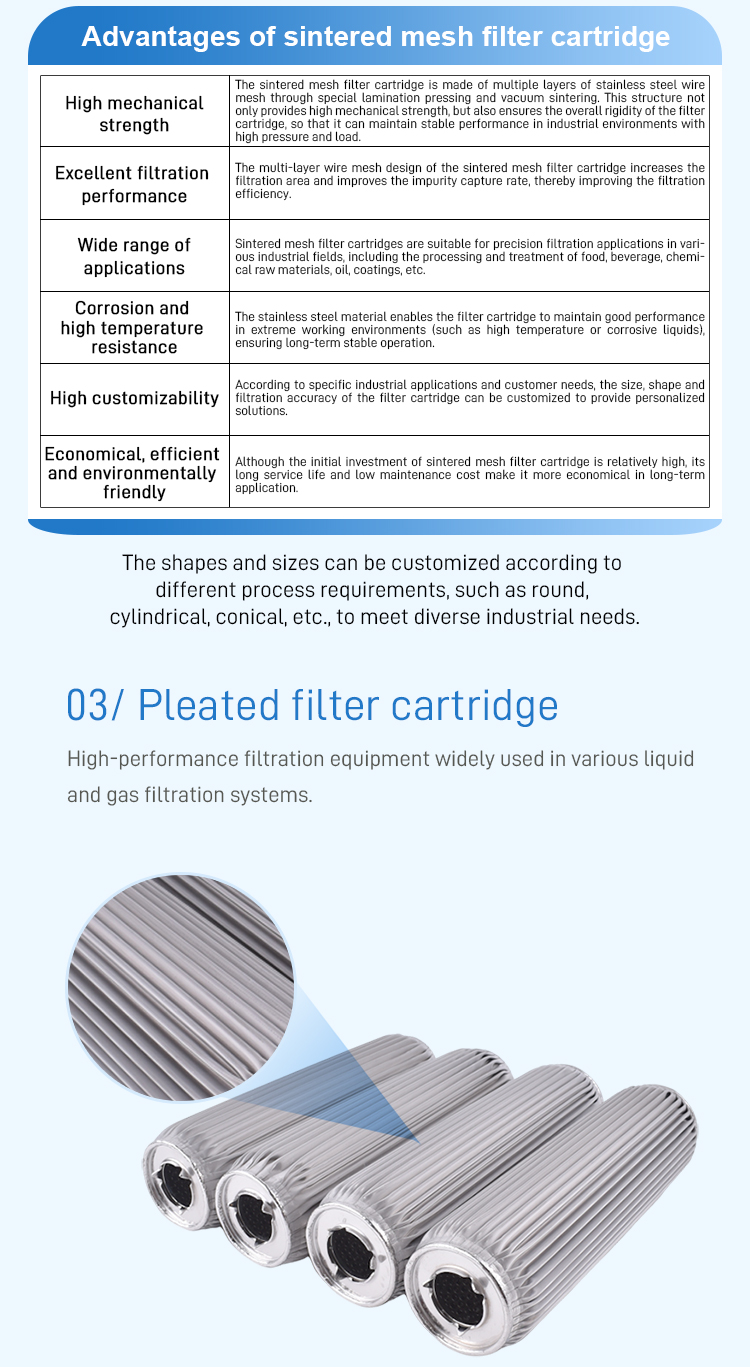

Material advantages: Made of stainless steel, it is corrosion-resistant, has high strength and can withstand high temperatures. It can adapt to harsh industrial environments and ensure the long-term stable operation of the equipment.

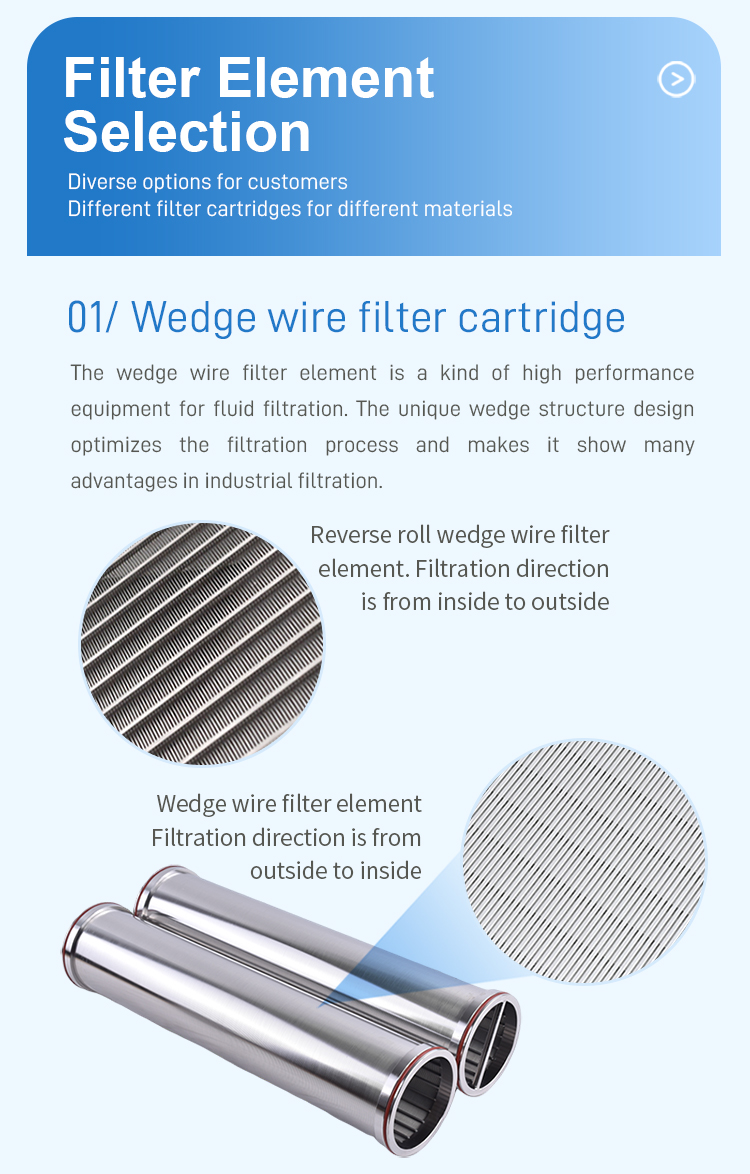

Diverse filtration accuracy: The filtration accuracy range is relatively wide, from 40 microns to 1000 microns. The appropriate accuracy can be selected according to actual needs to effectively intercept particle impurities of different sizes. For instance, the common stainless steel bag filter has a filtration accuracy of 1 to 100 microns, which can meet the demands of various industrial scenarios.

Reasonable structure: Simple structure and small volume. Some products adopt quick-installation or flange connection, which is convenient for installation and disassembly. Some filters have a reasonable internal structure design and a large filtration area, which can meet the filtration requirements of large flow rates.

Convenient operation and maintenance: Simple operation, some products can be automatically cleaned or backwashed, reducing manual operation. The filter screen or filter element is easy to replace, reducing maintenance costs and time.

Wide applicability: It is suitable for filtration of various liquids and gases, including water, oil, gas, etc., and can be applied in multiple industrial fields.

"Application

In the field of water treatment: It is used for tap water treatment, pre-treatment of industrial water, wastewater treatment, etc., to remove suspended solids, colloids, bacteria and other pollutants in water, improve water quality and protect subsequent water treatment equipment.

In the chemical industry: During the transportation of chemical raw materials and the feeding of reaction vessels, impurities in acid and alkali solutions, organic solvents, catalysts, etc. are filtered to prevent equipment blockage and catalyst poisoning, thereby enhancing product quality and production efficiency.

Food and beverage industry: During the processing of food and beverages, suspended particles, solid impurities and microorganisms in raw materials or products are removed, such as juice clarification, beer sterilization, mineral water filtration, etc., to ensure product quality and taste and meet hygiene standards.

Pharmaceutical industry: In the production of active pharmaceutical ingredients, the preparation of liquid medicine and filling, etc., intercept particle impurities and microorganisms in raw materials and liquid medicine to ensure that the drugs are sterile and free of foreign substances, and meet the production standards of drugs.

Oil and gas industry: During the processes of oil and gas extraction, processing and transportation, impurities, sediment and solid particles are filtered to protect the normal operation of equipment and pipelines, such as filtering impurities in the produced liquid of oil Wells in oil extraction.

In the electronic semiconductor industry: During the manufacturing process of electronics and semiconductors, remove fine particles, dust and other impurities to ensure the cleanliness of the production environment and improve the yield of products.

Other industries: It is also applicable to industries such as automotive manufacturing, steel and metallurgy, papermaking, plastics, irrigation, and shipping, providing reliable fluid filtration protection for various equipment and systems.