- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

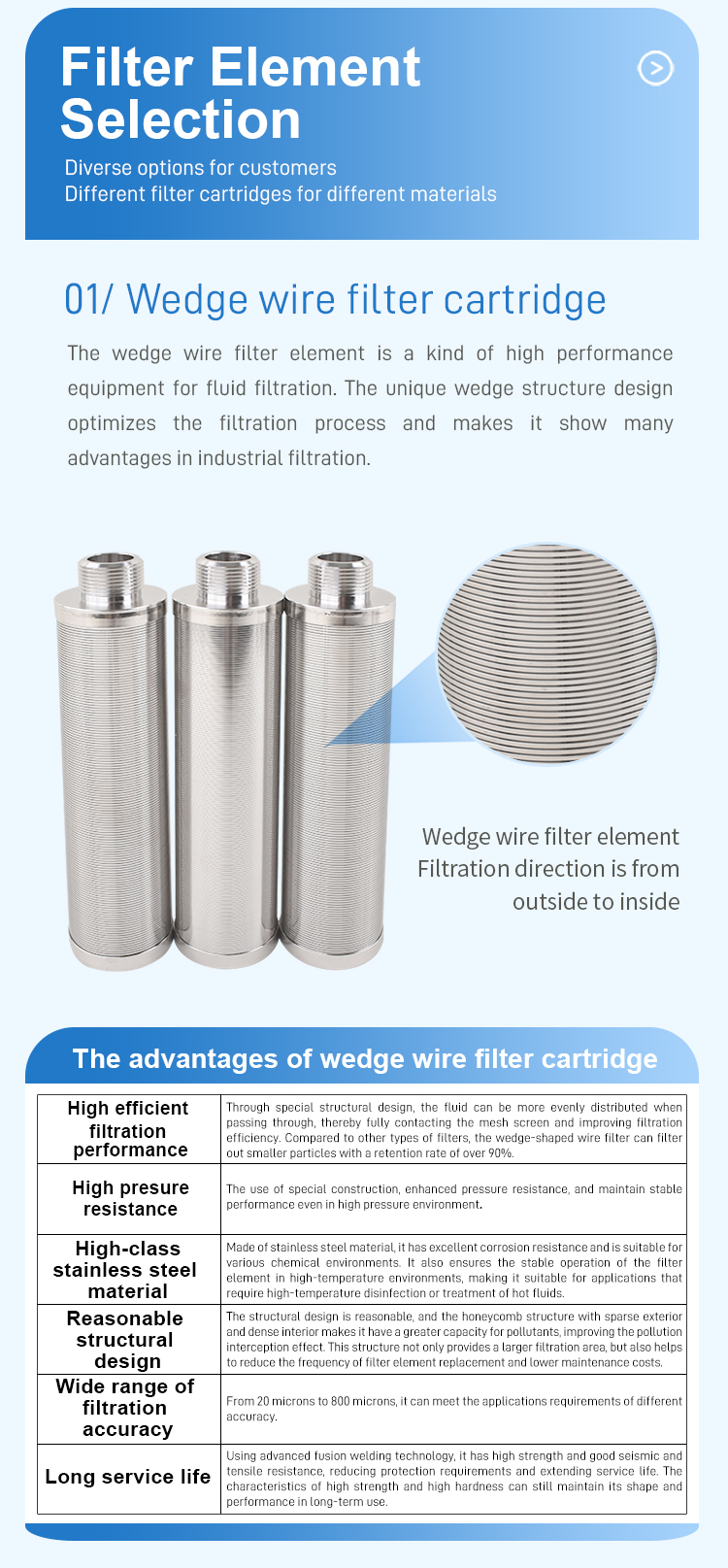

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

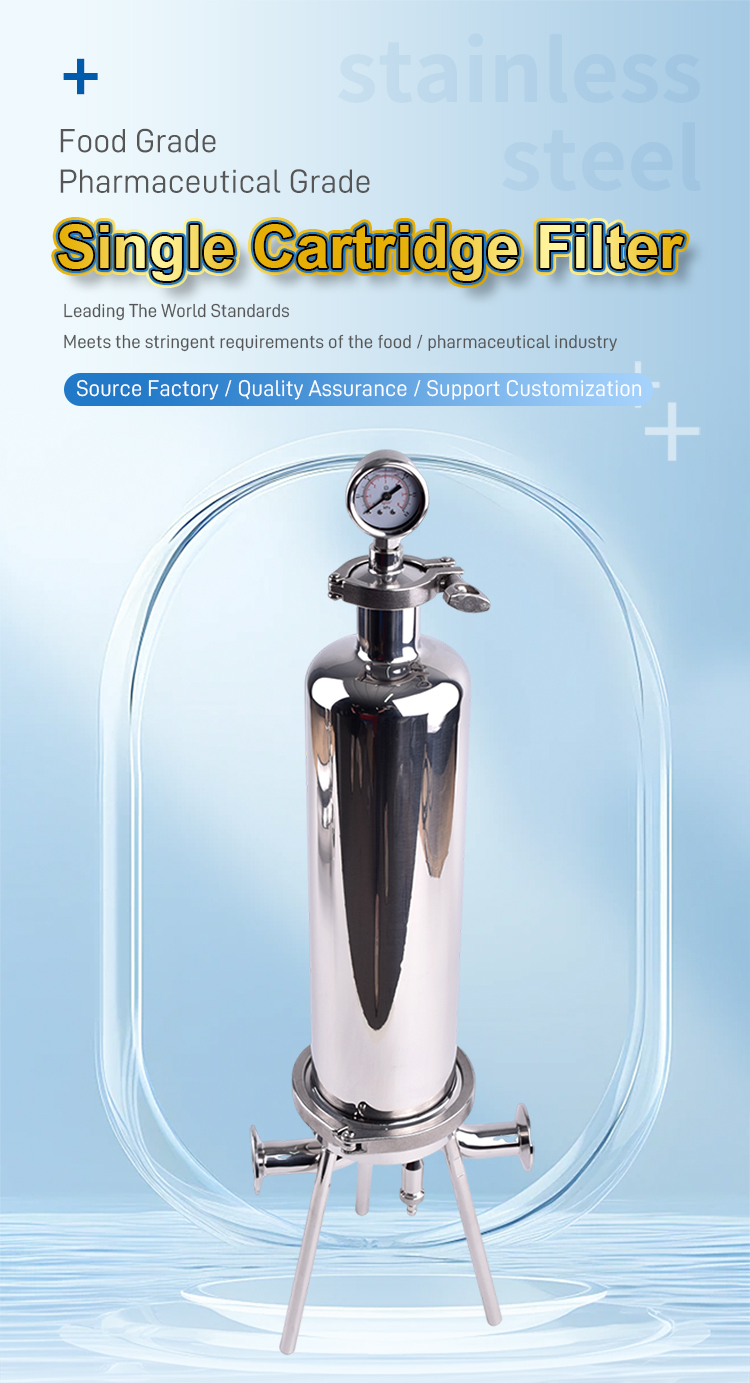

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

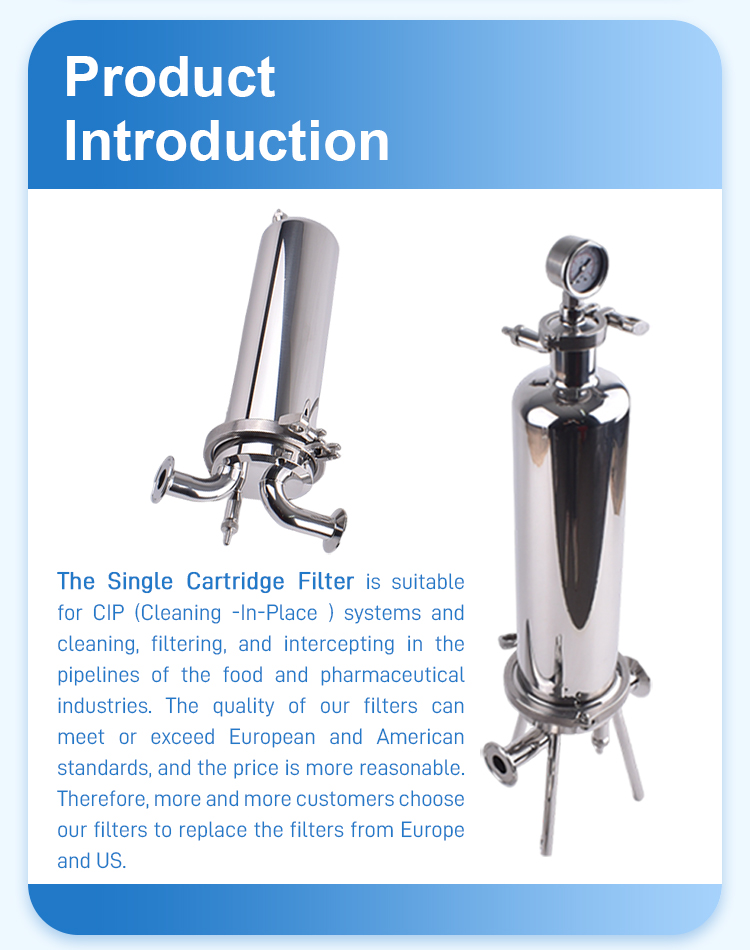

The stainless steel single-core filter is a filtration device that integrates multiple functions such as coarse filtration, fine filtration, and ultrafiltration. It is usually composed of a stainless steel cylinder, filter elements, etc., and intercepts impurities in the fluid through different filtration media.

Features

Superior material: Made of stainless steel materials such as 304 and 316L, it features high strength, high precision, and corrosion resistance, capable of adapting to various harsh working conditions and ensuring the long-term stable operation of the equipment.

Diverse filtration accuracy: The filtration accuracy range is relatively wide, from 0.1μm to 60μm. The appropriate accuracy can be selected according to actual needs to effectively intercept particle impurities of different sizes.

Reasonable structure: The structure design is compact and reasonable, occupying a small area, and is flexible and convenient to install and move. Some products are equipped with self-sealing devices to prevent fluid overflow when replacing the filter element.

Easy to maintain: Few vulnerable parts, no consumables, and low operation and maintenance costs; The operation and management are simple. Some products can achieve automatic backwashing without manual intervention.

Stable filtration performance: It can flexibly adjust the backwash pressure difference time and set value according to different water sources and filtration precision, ensuring the stability of the filtration effect.

"Application

Pharmaceutical industry: It is used in the production of large-volume parenterals and oral liquids in pharmaceutical factories, purification of raw materials, clarification of preparations, and treatment of process water, etc., to ensure the safety and efficacy of drugs.

In the food and beverage industry: During the production processes of beer, beverages, dairy products, syrups, etc., suspended particles, solid impurities and microorganisms in raw materials or products are removed to ensure product quality and taste.

In the field of water treatment: It is applicable to industrial water filtration, sewage treatment, drinking water purification, security systems of ultra-pure water equipment, etc., to remove suspended solids, colloids, bacteria and other pollutants in water.

Other industries: It is also applied in petroleum, printing and dyeing, electronics, environmental protection, fine chemicals, brewing and other industries, for clarifying and filtering various liquids, filtering filter residue for liquid-solid suspension and purifying gases, etc.