- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

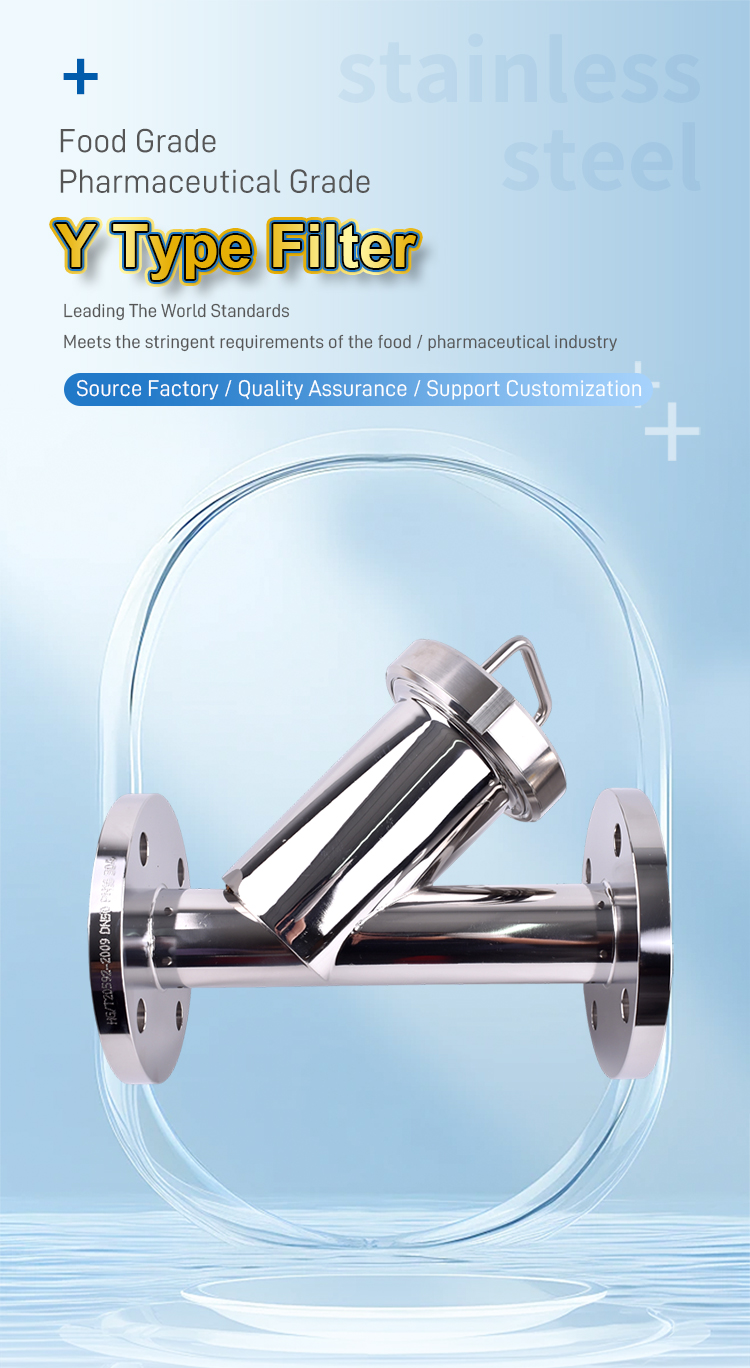

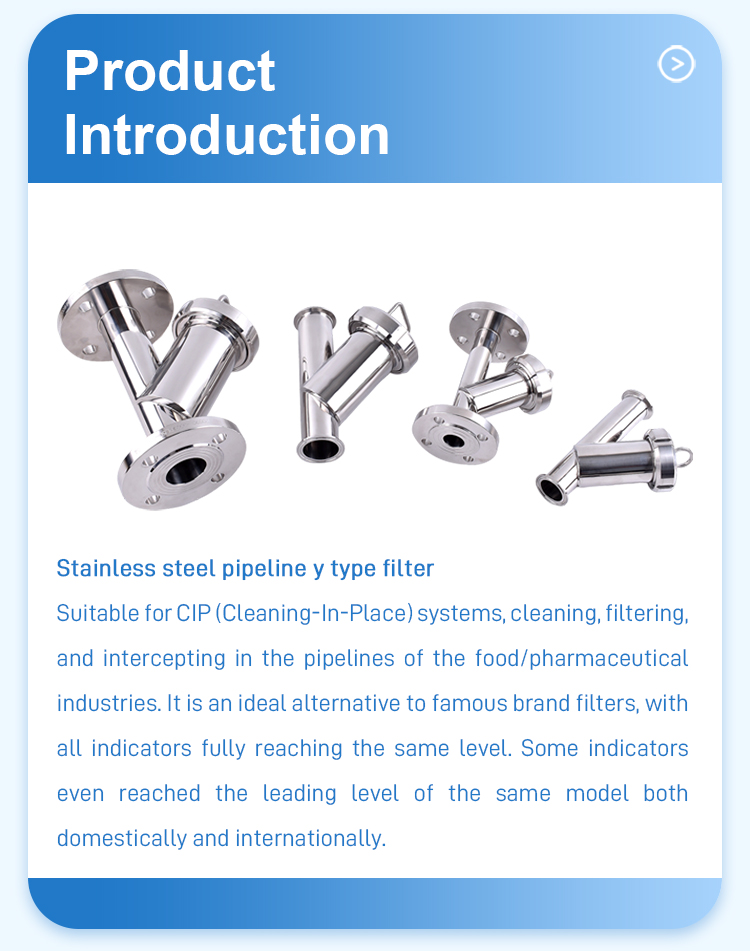

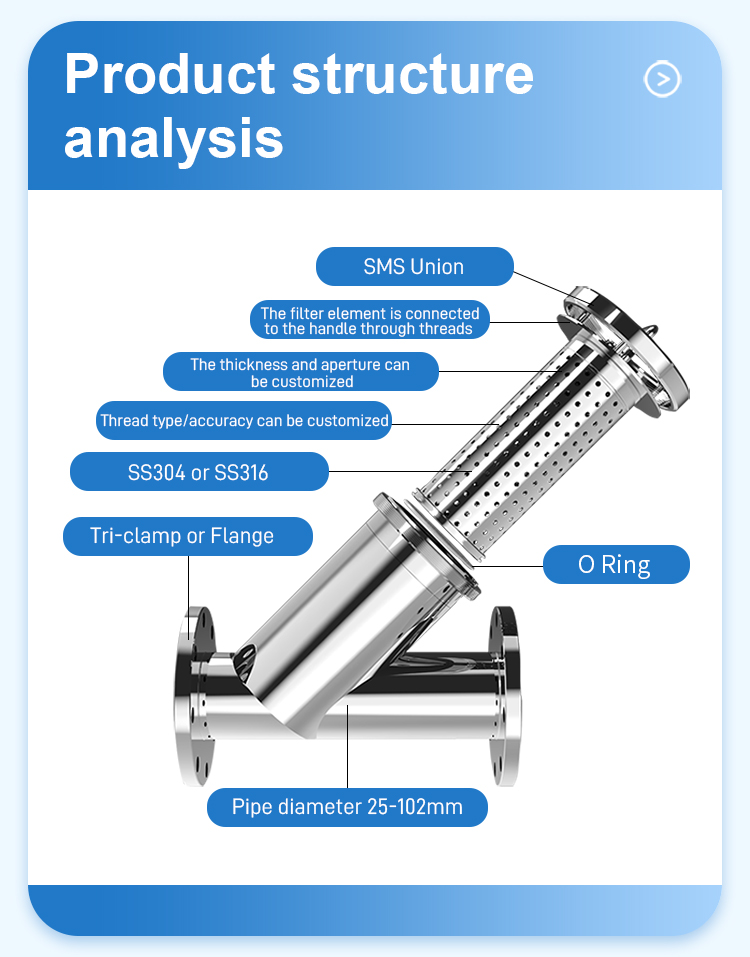

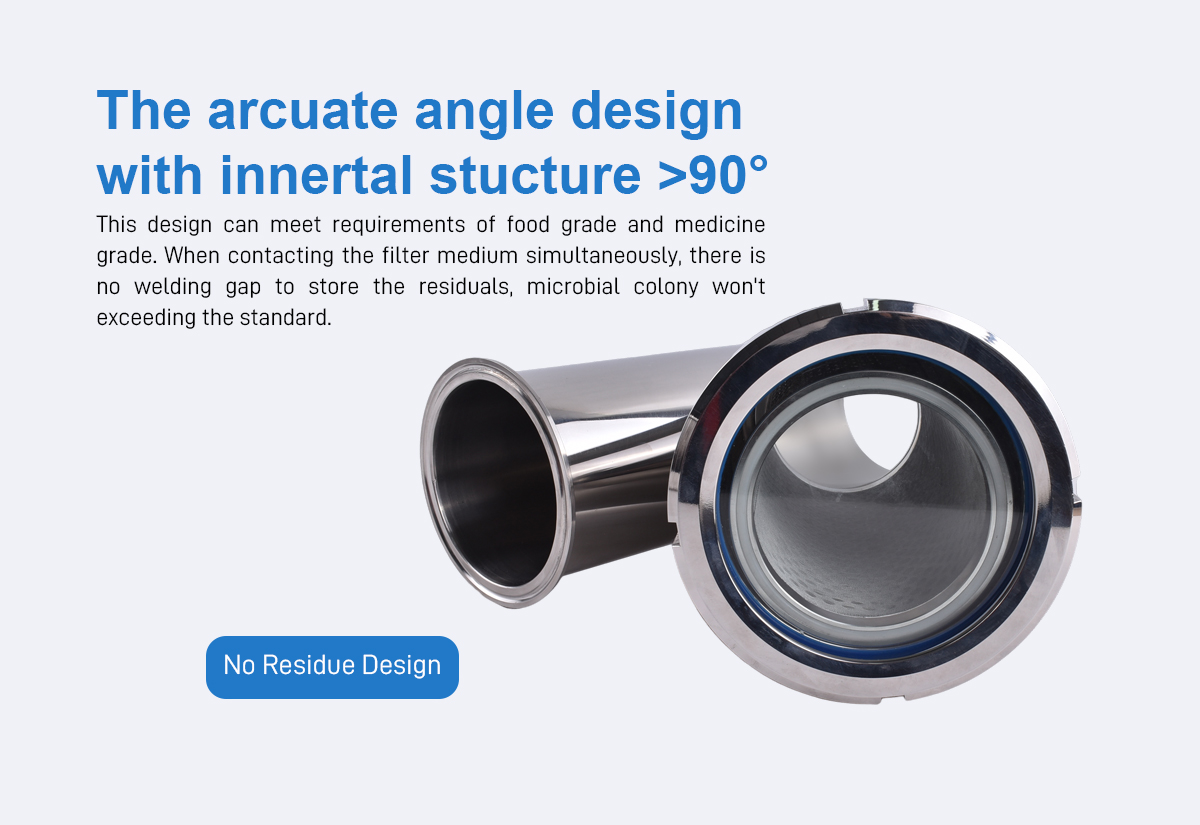

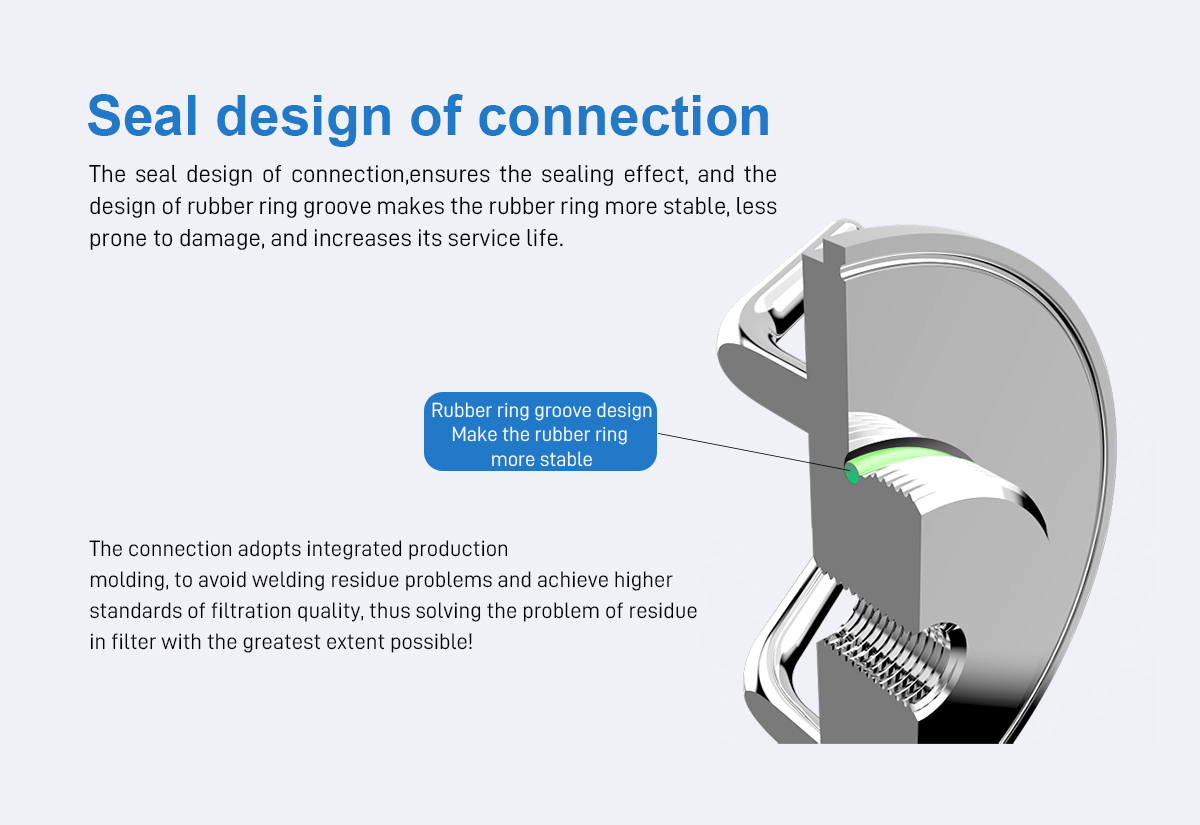

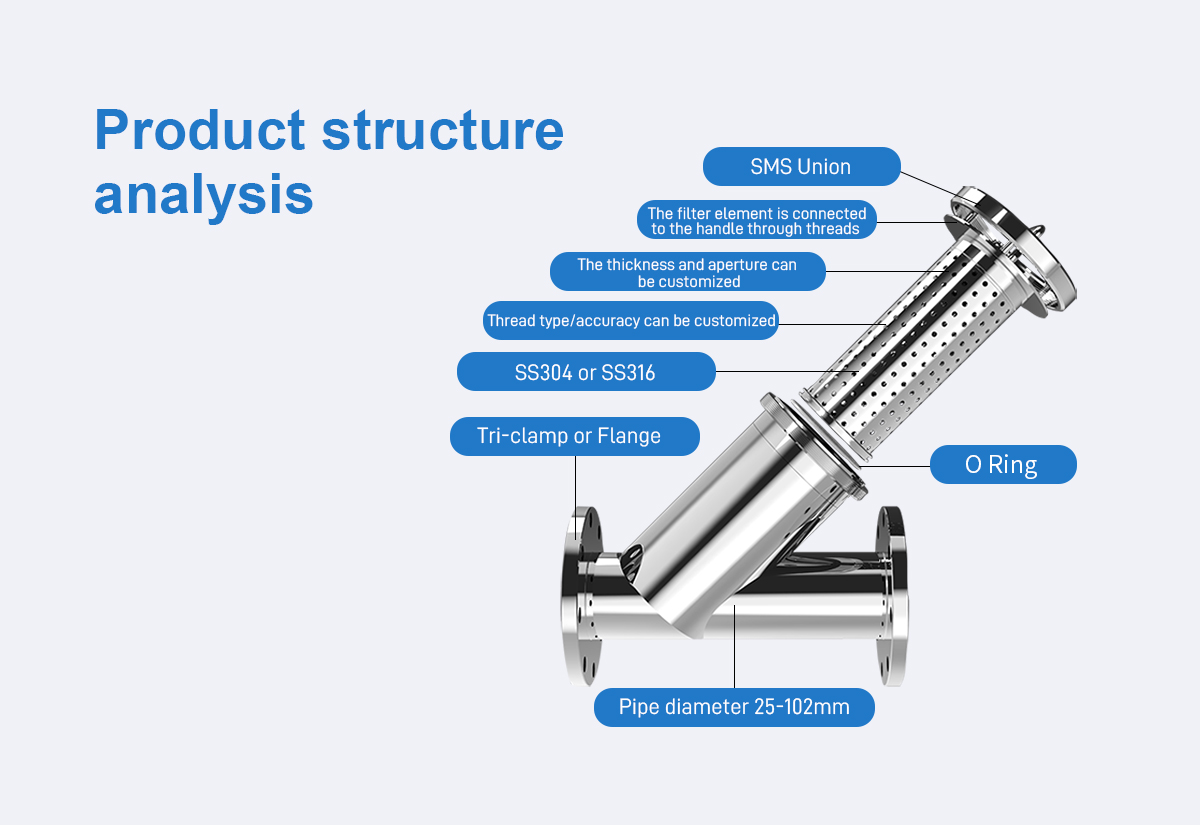

The stainless steel Y-type filter is an indispensable device on the pipeline for transporting media. It is usually installed at the inlet end of pressure reducing valves, safety valves, constant water level valves or other equipment to remove a small amount of solid particles from the fluid and protect the normal operation of valves and equipment. It is composed of a main pipe, a filter screen cavity and a sewage outlet. The filter screen is woven from 304 or 316L stainless steel, with a pore size accuracy of up to the micron level. Customized filter screens ranging from 10 to 500 mesh can be provided as required. When the fluid flows in from the main pipe, impurities are intercepted by the filter screen. The clean fluid flows out through the branch pipe, and the deposited impurities are regularly discharged through the bottom sewage outlet.

Features

Reliable material: Made of stainless steel, it is corrosion-resistant, has high strength and good toughness, can adapt to harsh working conditions, and has a long service life.

High filtration efficiency: The filter screen precision can reach the micron level, effectively intercepting suspended solids, particles, impurities, and some bacteria, viruses and other microorganisms in the fluid. It can be customized with 10-500 mesh filter screens according to the working conditions to ensure the efficient operation of the system.

Advanced structure: The Y-shaped structure ensures smooth fluid flow and low pressure loss, typically with a pressure drop of 0.05 to 0.1 meters of water column at the rated flow rate.

Easy maintenance: The filter cartridge is detachable, facilitating cleaning and filter screen replacement. Some models support online cleaning, reducing downtime.

Wide application: It is suitable for various fluids such as water, oil and gas, and can meet the needs of different industries.

"Application

In the industrial field: In the production of chemical engineering and petrochemicals, it filters impurities from weakly corrosive materials (such as water, oil products, ammonia, hydrocarbons, etc.) and corrosive materials (such as caustic soda, soda ash, concentrated and dilute sulfuric acid, carbonic acid, aldehyde acid, etc.) to protect compressors, pumps, instruments and other equipment. It is also used in refrigeration systems to filter impurities from low-temperature materials (such as liquid methane, liquid ammonia, liquid oxygen and various refrigerants), ensuring the normal operation of equipment.

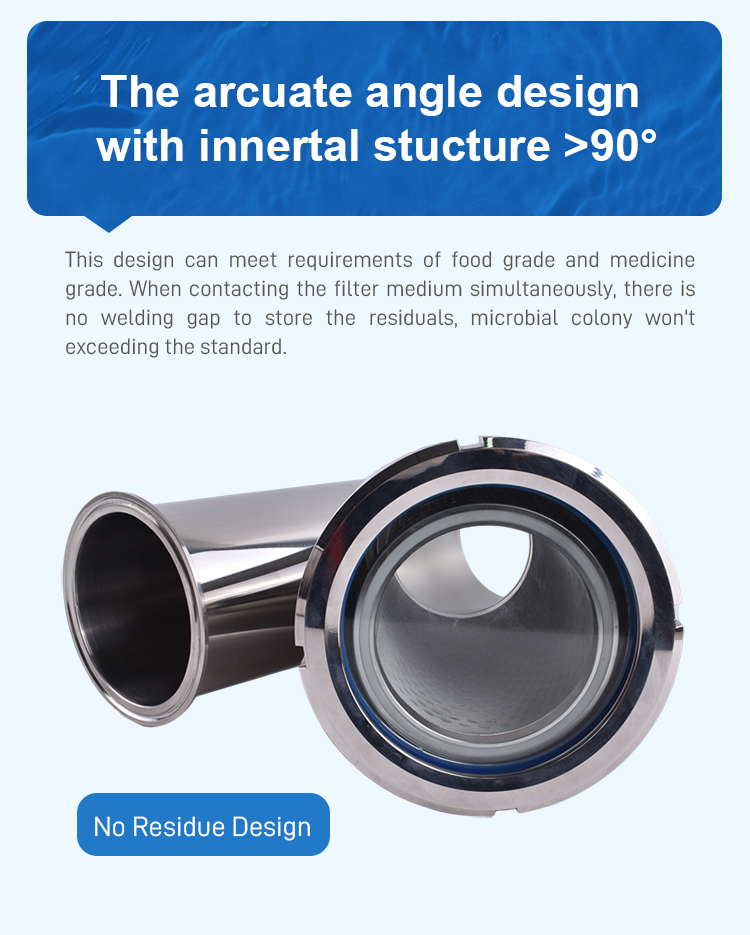

Food and beverage industry: 316L stainless steel filters that meet food-grade standards can be used in the production processes of beer, beverages, dairy products, syrup, etc., to remove suspended solids and other impurities, ensuring stable product quality.

Civil field: Widely applied in household gas systems, central air conditioning circulating water systems, etc., it removes impurities, protects equipment, and enhances usage efficiency and safety.