- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

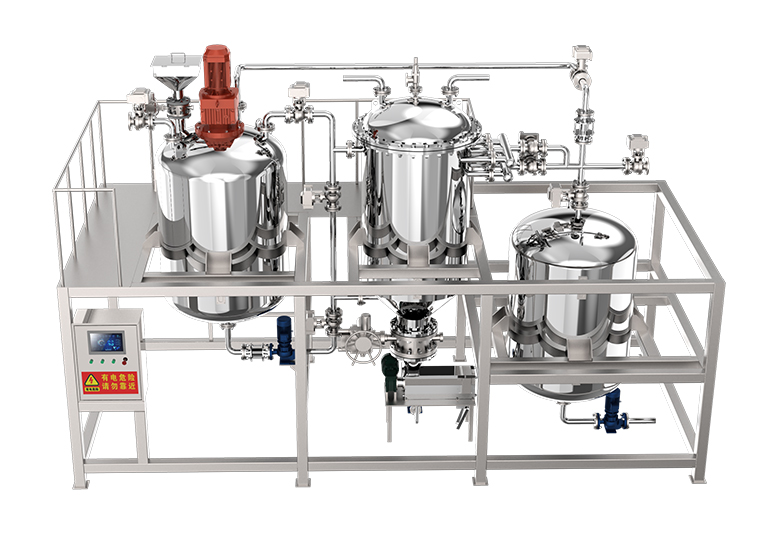

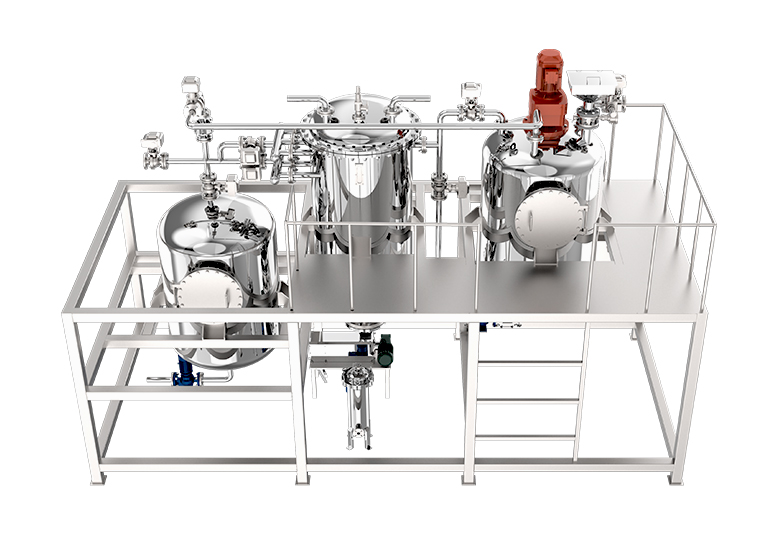

The bundle filter is a highly efficient, energy-saving, and automatically sealed filtration precision clarification device, often also known as a tube bundle filter or candle filter. Its filtration system integrates tubular filter elements installed on the liquid collection pipe for filtration.

Features

Good sealing performance: no leakage, no environmental pollution, capable of withstanding high pressure, extended working time, and the residual liquid can be recovered after filtration.

High filtration accuracy: By using imported French filter candles or strictly controlling the pore size and distribution of the filtration medium, the filtration accuracy can be guaranteed. For instance, some can reach 0.1-100 μm, achieving complete filtration in one go. Expensive catalysts can be intercepted by 99%.

High degree of automation: The system is controlled by PLC programming and operated by touch screen. The entire filtration process is automated and can also be configured automatically according to the pipeline.

Good backwashing effect: The filter elements adopt backwashing, which is effective, convenient and reliable. The filter cake can be washed and dried to achieve the maximum economic benefits.

Reasonable structure: Inside the casing, the candle tubes (available in both metal and non-metal types) are covered with filter cloth. After filtration, the drying of the filter cake, its discharge, and the cleaning of the filter cloth can all operate automatically. It has no drive device, a simple structure and can handle a large filtration area. In combination with the candle-type core structure design, it can achieve no residual liquid discharge inside the shell, and the bottom slag discharge is convenient, which is conducive to vertical slag discharge and approaches the full sanitary grade requirements.

Diverse styles: There are various structures of candle filter elements (such as stainless steel 304, 316L, plastic PP, PPS, PTFE, etc.), which can meet different filtration requirements.

"Application

Food industry: Activated carbon decolorization filtration for sugar solutions such as granulated sugar and glucose, as well as clarification filtration for alcoholic beverages, fruit juices, and soft drinks.

Chemical industry: It is used for crystal separation in filtration in petrochemical, inorganic chemical, organic chemical and other fields, filtration and separation of various catalysts, decolorization filtration of chemical products, impurity removal of electrolytes, degreasing and slag removal of metals, slag removal in phosphating, concentration and thickening of chemical products, etc.