- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

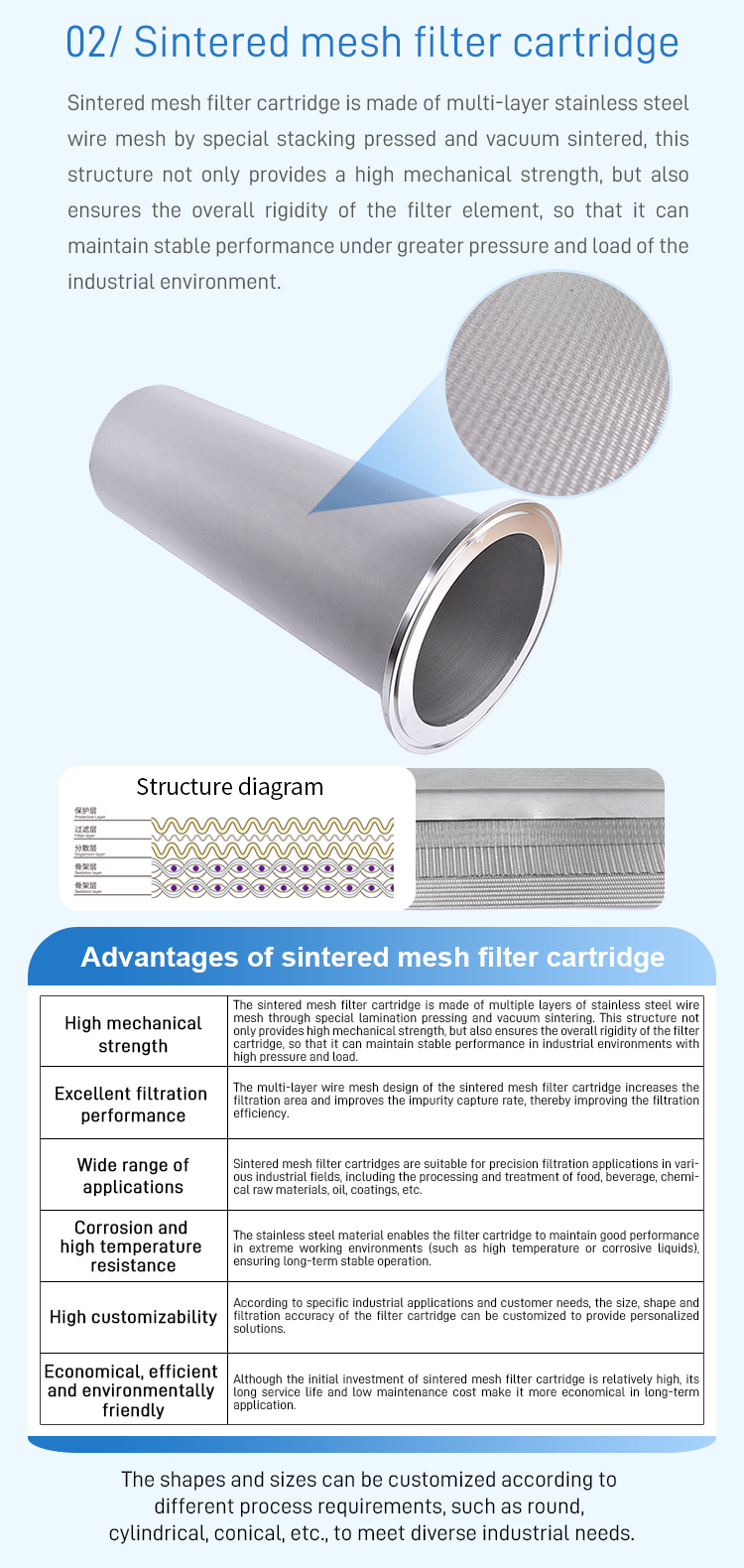

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

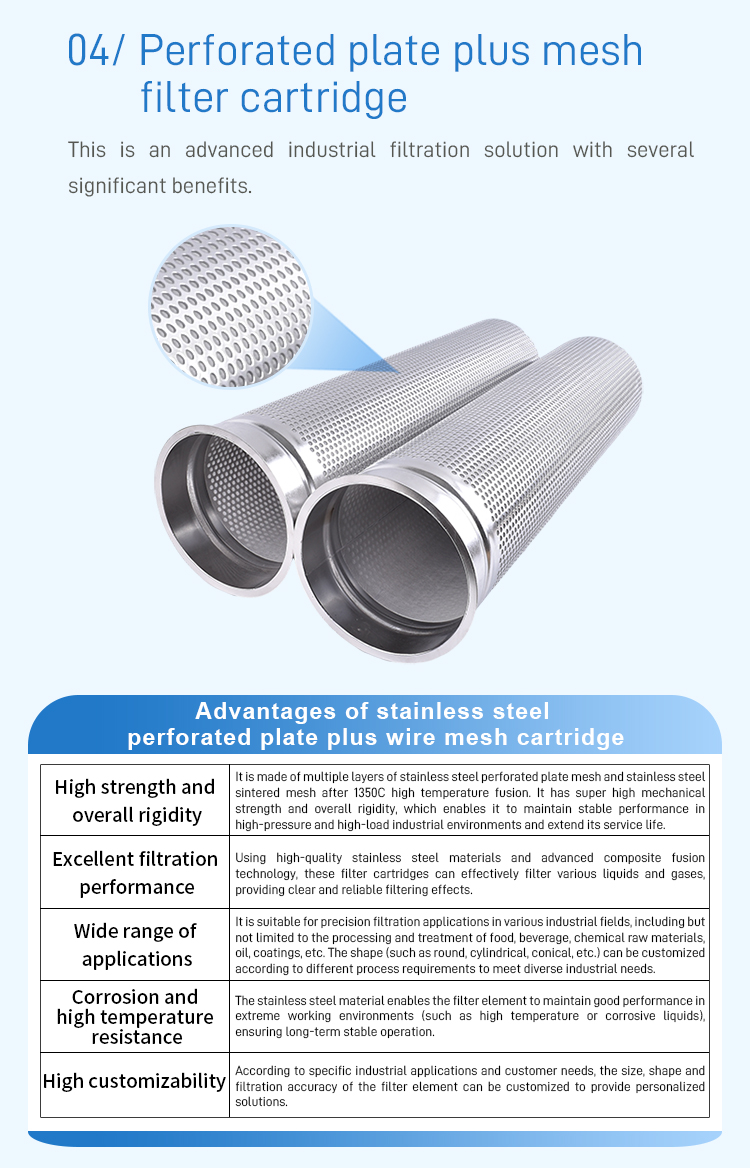

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

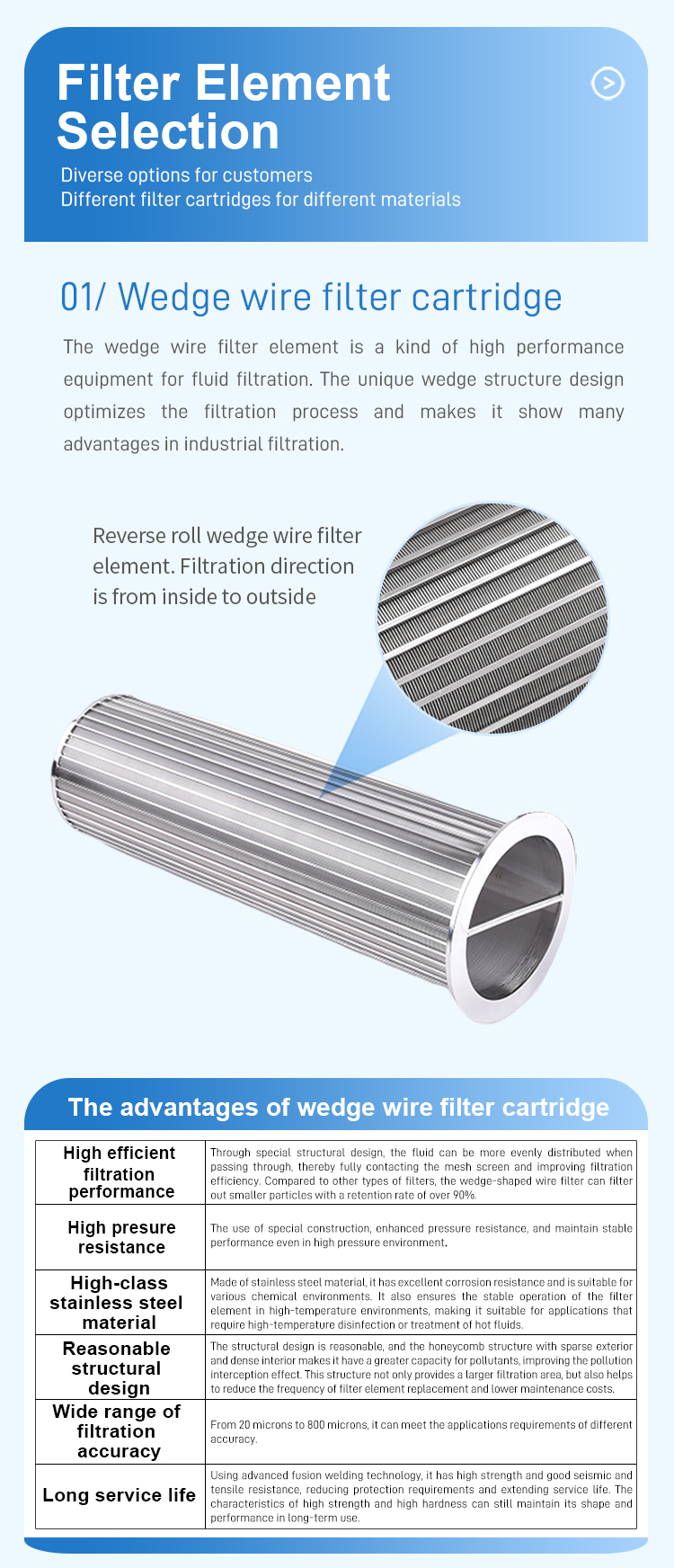

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

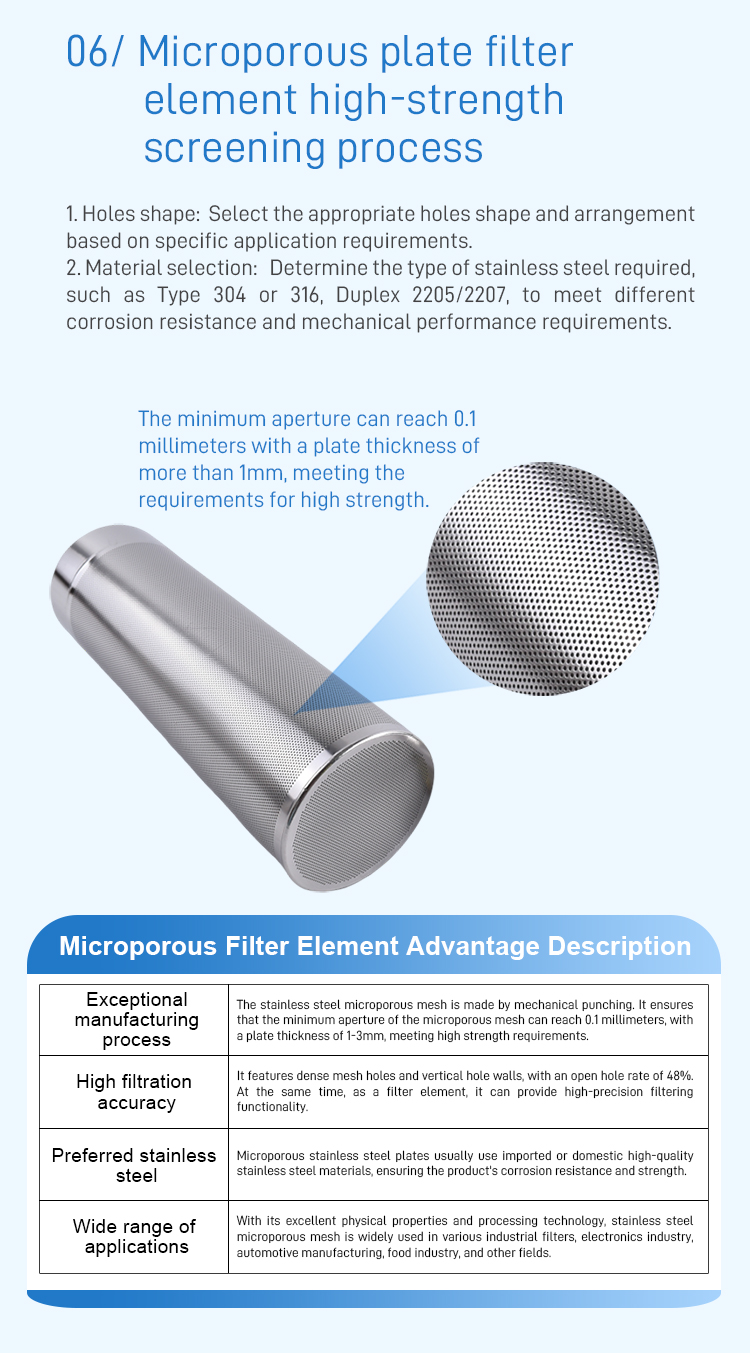

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

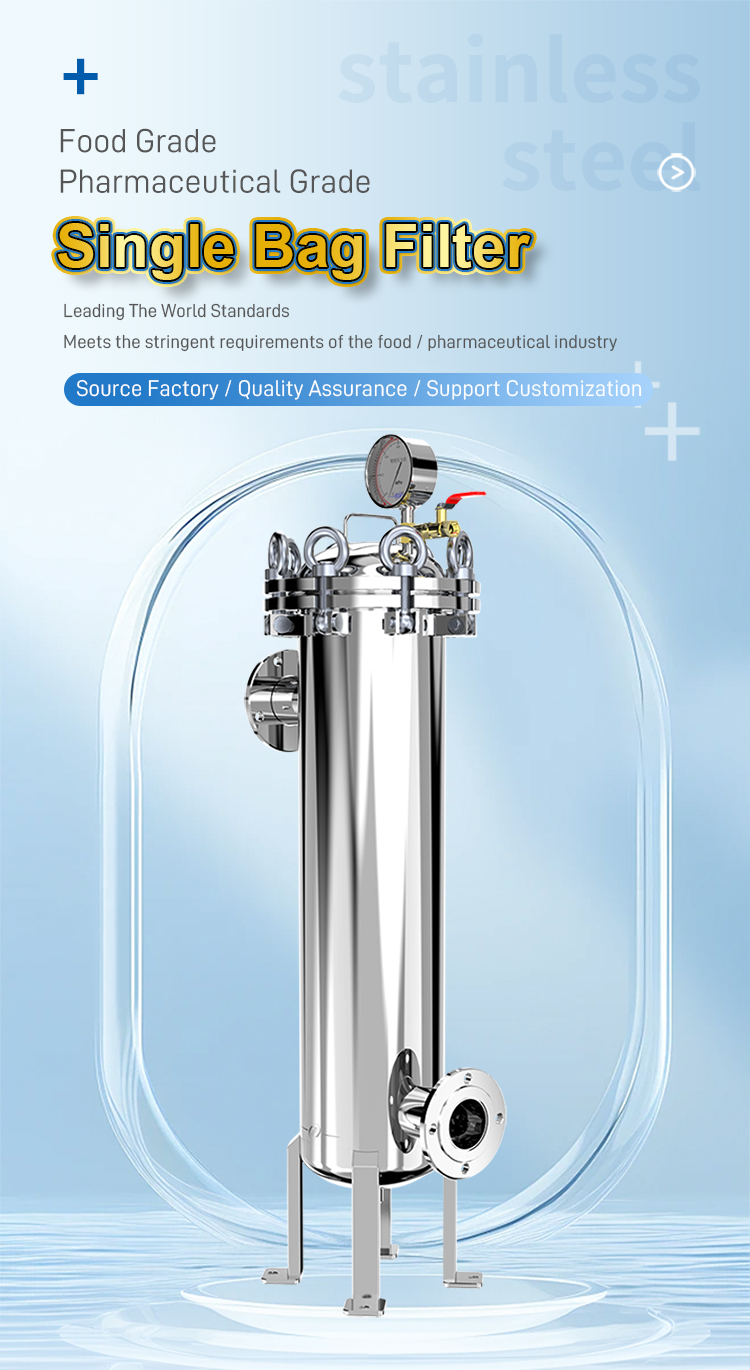

Stainless steel multi-bag filter

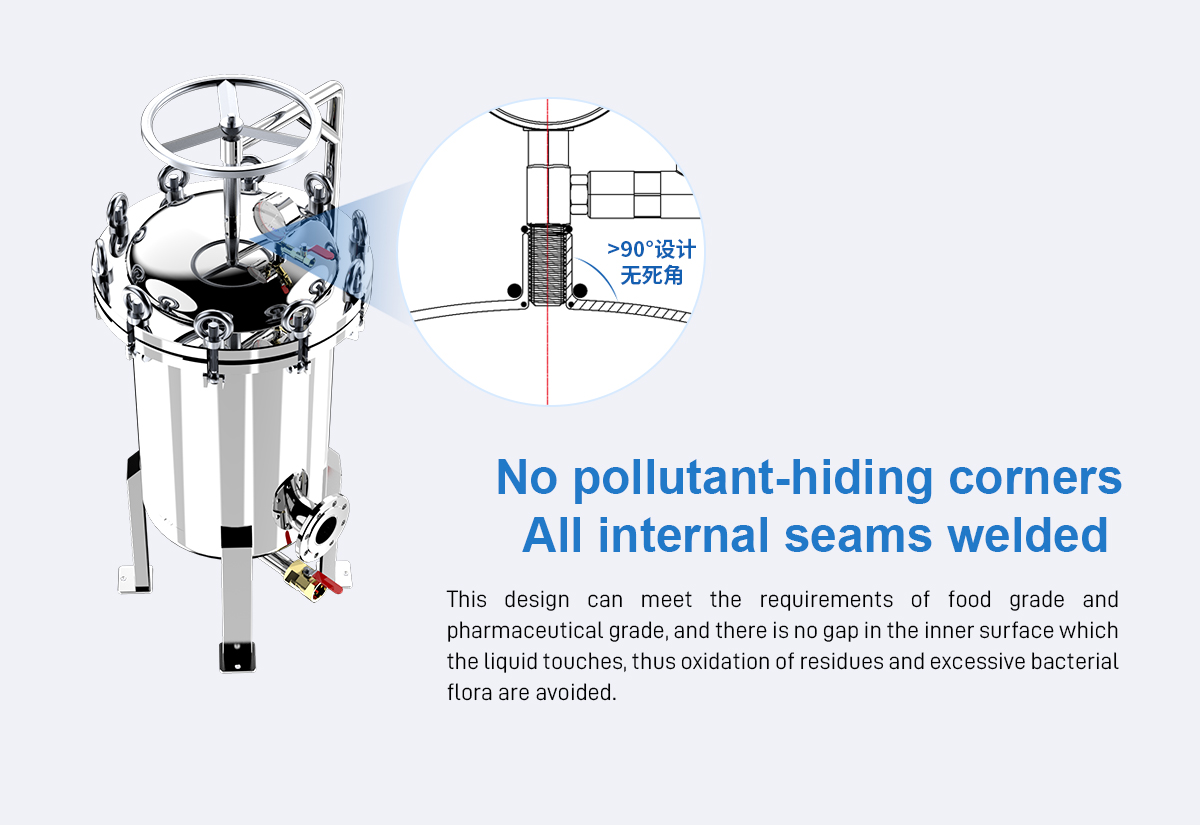

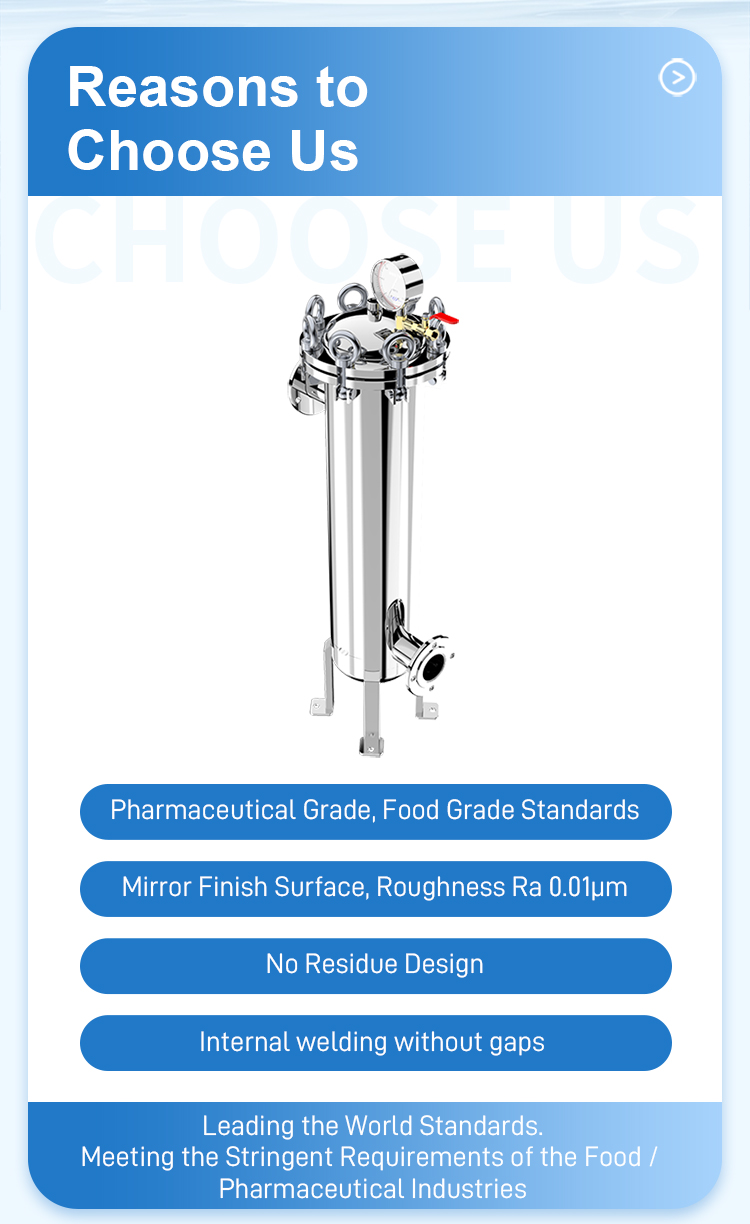

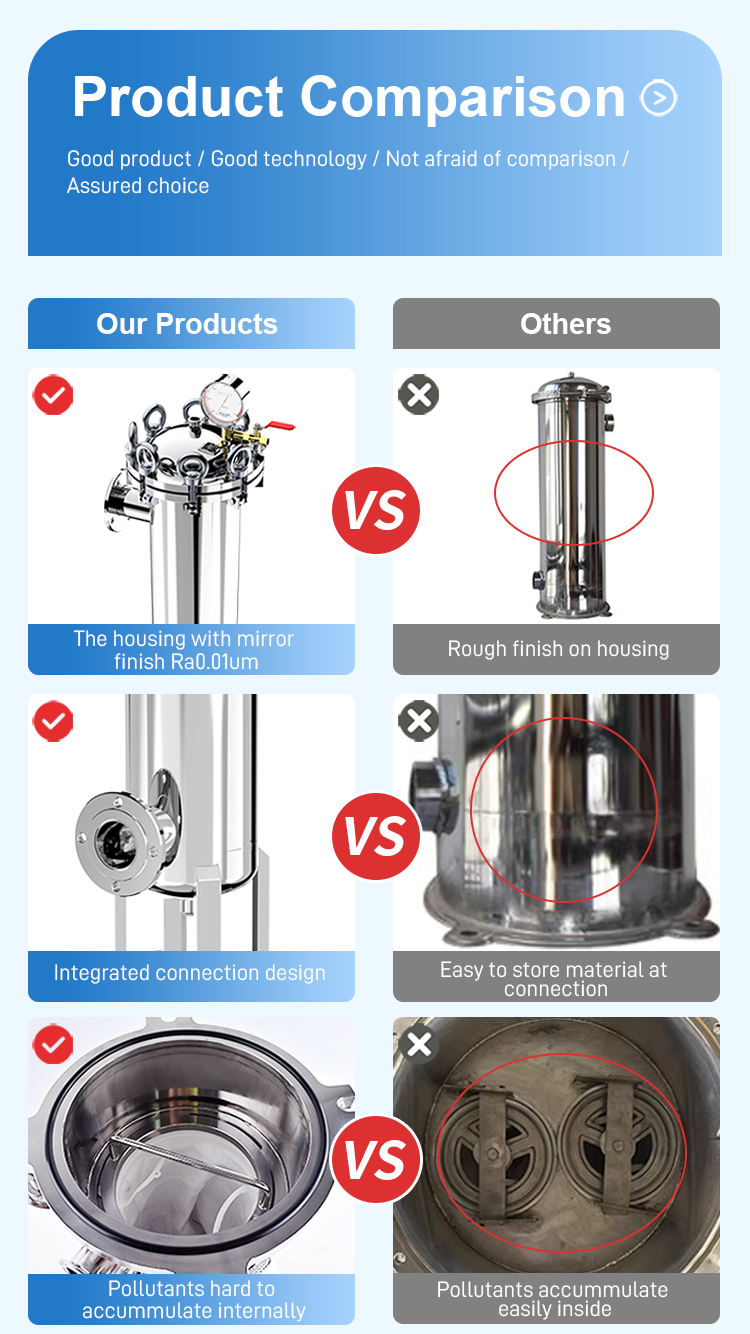

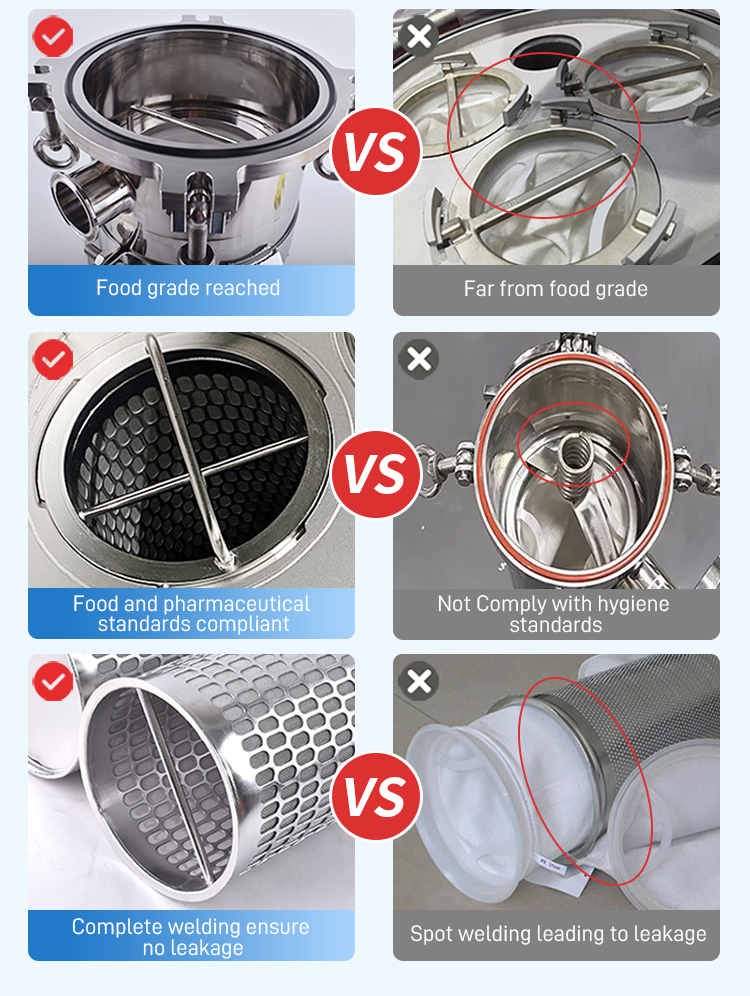

The stainless steel multi-bag filter is a precision filtration device, made of high-quality stainless steel and composed of a shell, filter bags, a sealing system, etc. The liquid to be filtered is input by the pump. After the impurities are retained by the filter bag, the clean liquid is discharged. When the impurities accumulate to the set pressure difference, the filter bag needs to be replaced.

Features

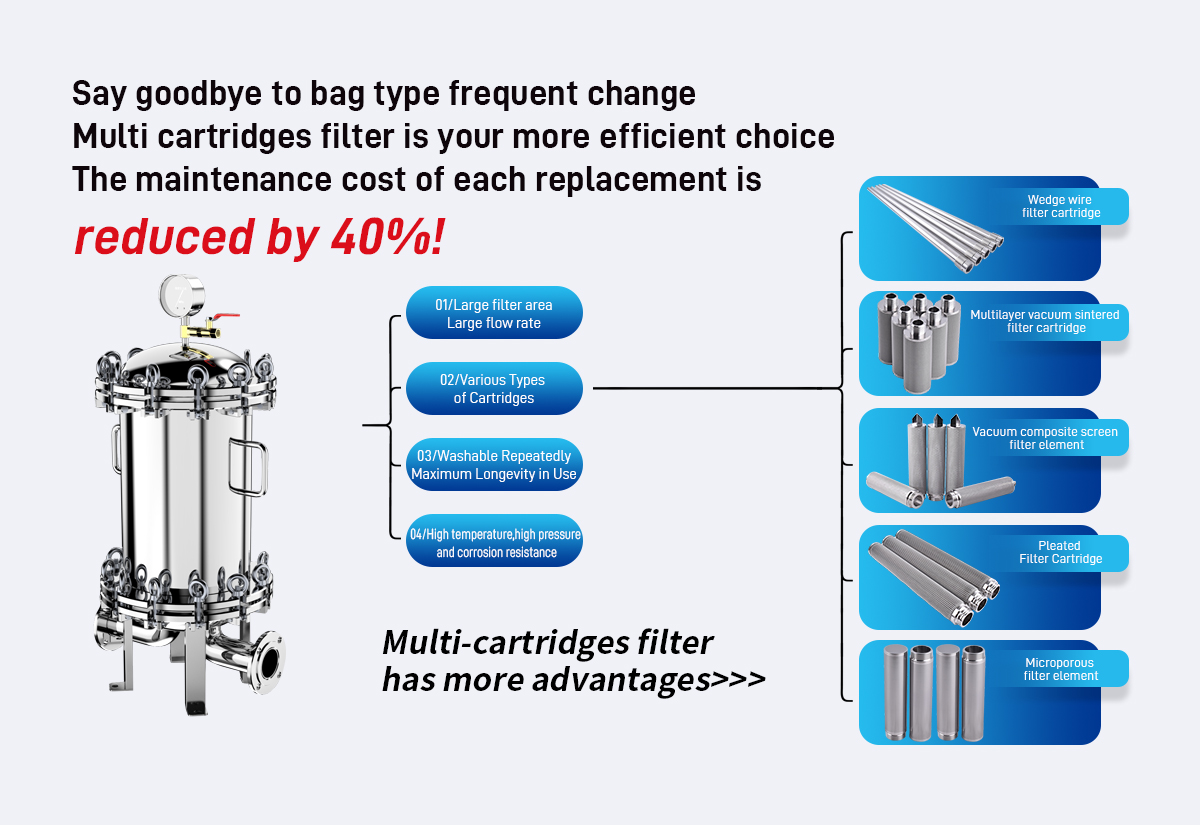

Large processing capacity: The multi-bag parallel design features a large processing capacity, small volume, and high dirt-holding capacity. The single-machine flow rate can reach 80-1080 m³/h, which can meet the demands of large-scale production.

Easy operation: Replacing filter bags is convenient and quick, and the filter does not require cleaning, saving labor and time. Some designs feature quick-opening clamps, spring assist devices, etc., to enhance the efficiency of opening the lid.

High filtration accuracy: The filtration accuracy of the filter bags is constantly improving and can reach 0.5μm, which can meet the filtration accuracy requirements of different industries.

Good sealing performance: O-rings and quick-opening mechanisms ensure no leakage, effectively guaranteeing the filtration quality.

Low pressure loss: It can withstand relatively high working pressure, has low pressure loss, low operating costs, and obvious energy-saving effects.

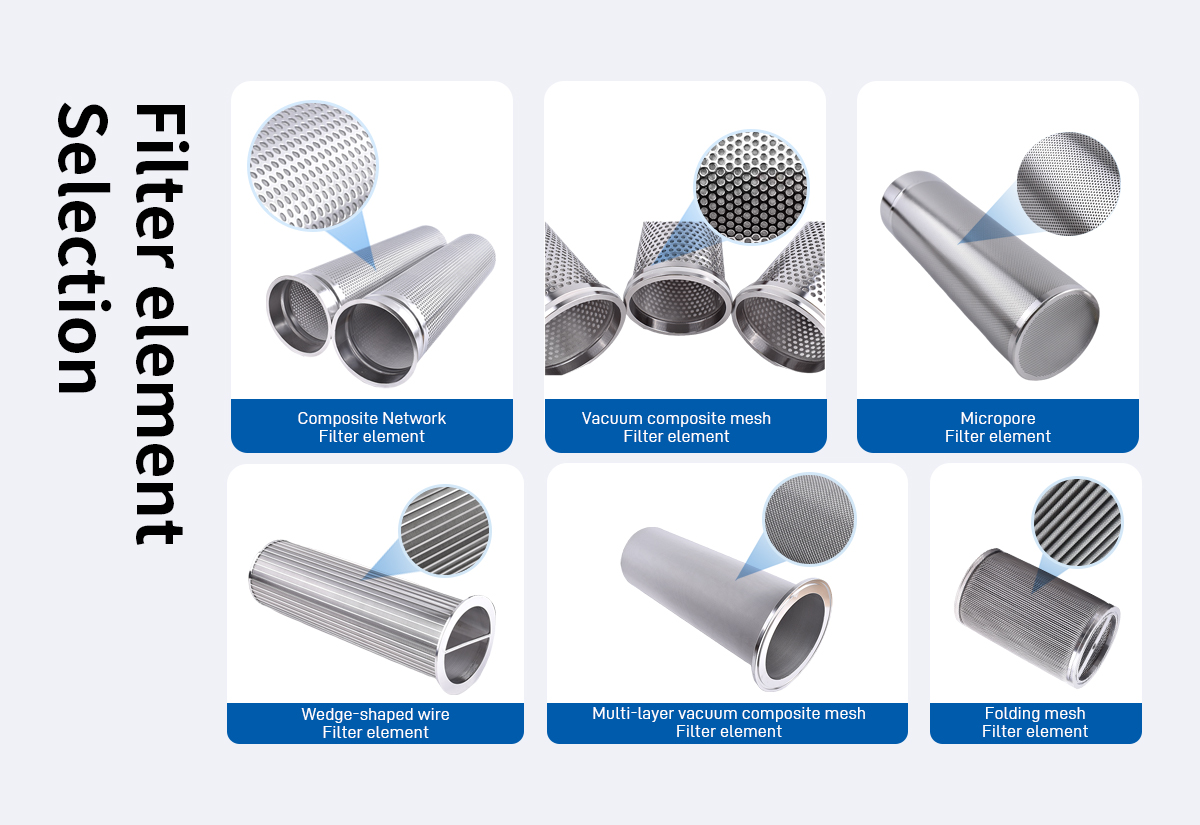

Flexible application: The filter bags can be matched in various ways. Different filter bags can be selected according to the working conditions to achieve coarse filtration, medium filtration or fine filtration. There are various installation methods, including flange, quick-installation, threaded, etc.

Low cost: The filter bags can be reused after cleaning, and the filtration function of one liquid filter bag is equivalent to 5 to 10 times that of a filter element, which can reduce operating costs.

"Application

It is widely applied in multiple industries, including food and beverage (such as clarification and filtration of fruit juice, beer, edible oil, etc.), chemical and pharmaceutical (purification of acid and alkali solutions, recovery of catalysts, clarification and filtration of medicinal liquids), environmental water treatment (pretreatment of industrial wastewater, seawater desalination), electronic electroplating (preparation of ultrapure water, purification of plating solutions), mechanical processing, papermaking, dyeing and printing, etc. It is also suitable for handling acidic and alkaline solvents, oils, high-viscosity liquids, etc., with an applicable pH range of 0 to 14.

Related Products

-

Multi-core filter

-

Stainless steel multi-bag filter

-

Online filter (external scraper

-

Dynamic self-cleaning filter

-

Stainless steel gas filter

-

Stainless steel respirator

-

Stainless steel Y-type angled filter

-

Stainless steel Y-type filter

-

Stainless steel Y-type filter

-

Straight-through pipe filter

-

Stainless steel magnetic filter

-

Stainless steel wedge-shaped wire filter element

-

Stainless steel pleated mesh filter element

-

Stainless steel microporous filter element

-

Stainless steel plate mesh filter element

-

Stainless steel composite mesh filter element