- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

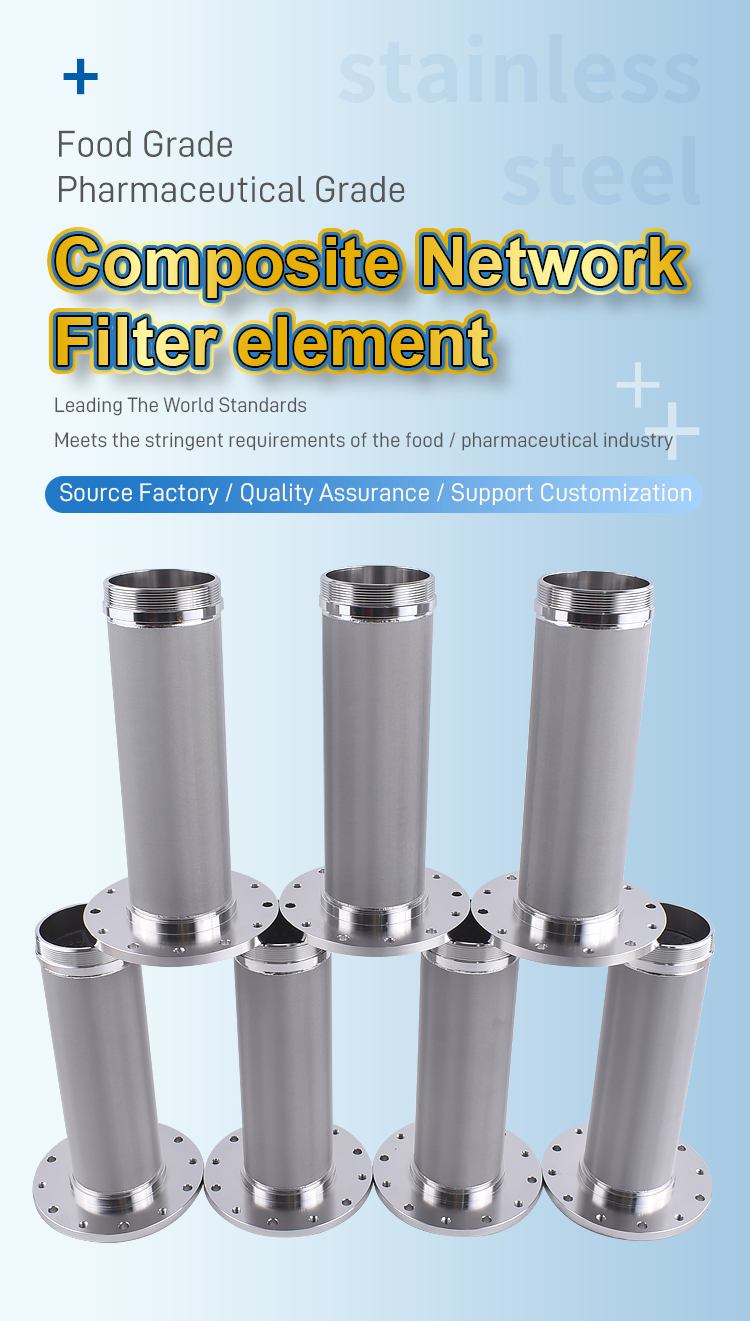

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

Stainless steel fiber felt filter element

Stainless steel fiber felt filter elements are made of stainless steel fibers through high-temperature sintering. They are a type of porous and deep filtration material, often processed by folding technology from stainless steel fiber sintered felt and stainless steel woven mesh.

Features

Excellent filtration performance: high porosity, good air permeability, low resistance, and low operating pressure difference. When folded, it has a large filtration area and a large dirt-holding capacity. It can control the attainment of high filtration accuracy and large dirt-holding capacity.

High temperature and corrosion resistance: It can be used normally below 500℃ and can withstand environments such as nitric acid, sulfuric acid, dilute hydrochloric acid (5%), acetic acid, liquid hydrogen, and liquid nitrogen. It is suitable for filtering highly viscous liquids.

Easy to clean and regenerate: It has excellent regeneration performance and can be reused after chemical cleaning, high-temperature cleaning and ultrasonic cleaning.

Good chemical compatibility: All-stainless steel structure, suitable for various chemical media.

Other features: Good strength, not easy to fall off, easy to clean; The forming process is excellent and can be processed and formed in one go according to the customer's drawings. The pores are uniform, the internal structure is stable, and there is no particle shedding. Good air permeability and easy to reverse blow clean. Wear-resistant and impact-resistant, with good mechanical properties.

"Application

Chemical industry: It is used in the production of fine chemical products, gas oil filtration in heavy coking units of the petrochemical industry, and circulating oil filtration in hydrocracking, etc.

Pharmaceutical industry: Impurity removal of active pharmaceutical ingredients, decarbonization and decolorization of pharmaceutical intermediates, and precision filtration, etc.

Food processing industry: Remove impurities in beverage production and dairy product processing to ensure food safety and hygiene.

Water treatment field: It is used for industrial wastewater treatment, drinking water purification, and the removal of suspended solids and microorganisms in water. It is also used for security filtration in ultrafiltration, RO and EDI systems.

In terms of gas filtration: It is used for filtering, dust removal, sterilization, and oil mist removal of high-temperature gases, steam, compressed air, catalysts, etc. It can also be used for gas purification and gas buffering, etc.

Related Products

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element

-

Stainless steel fiber felt filter element