- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

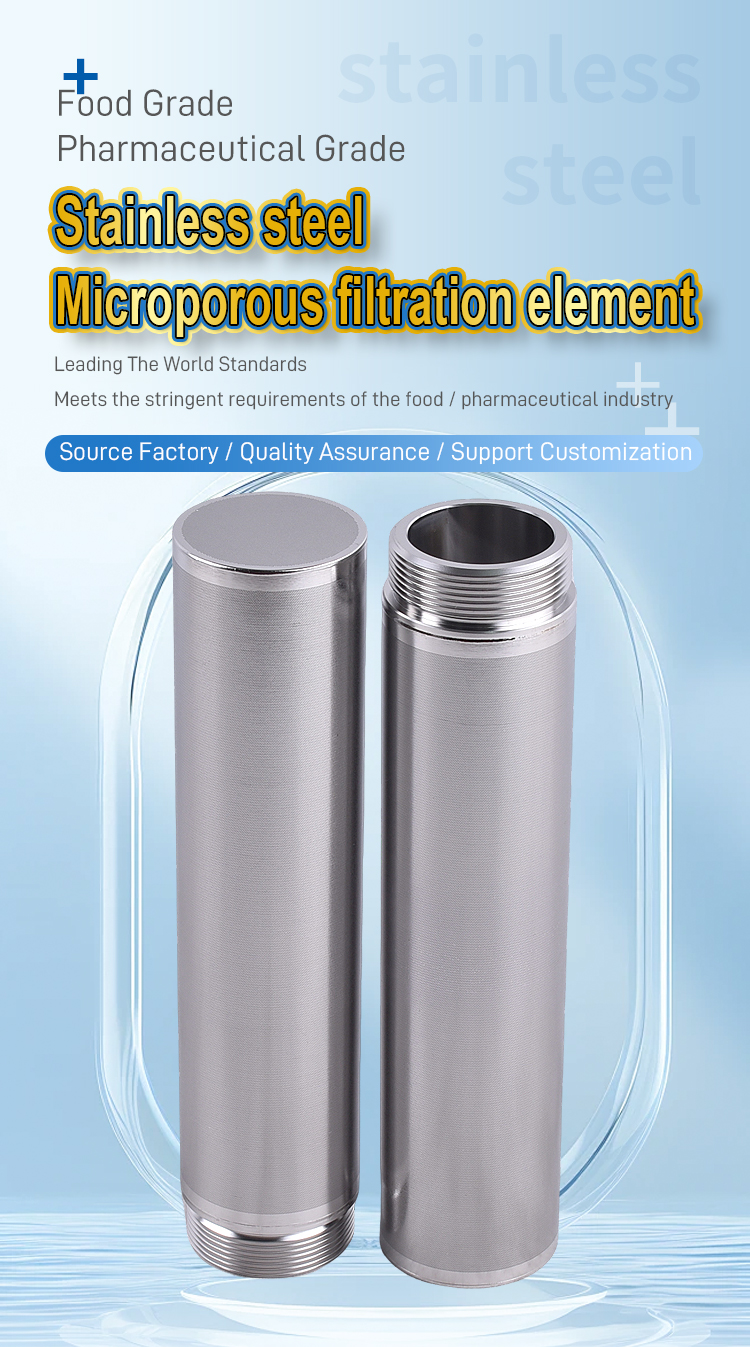

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

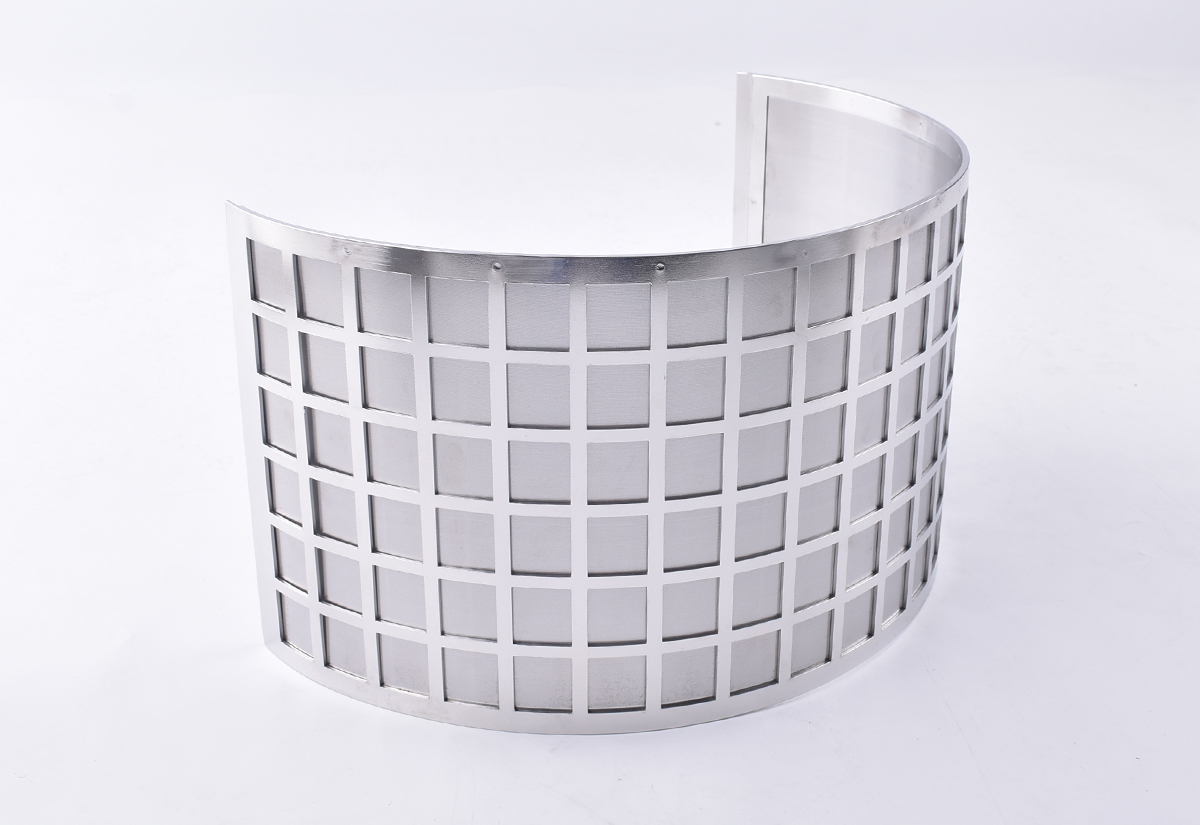

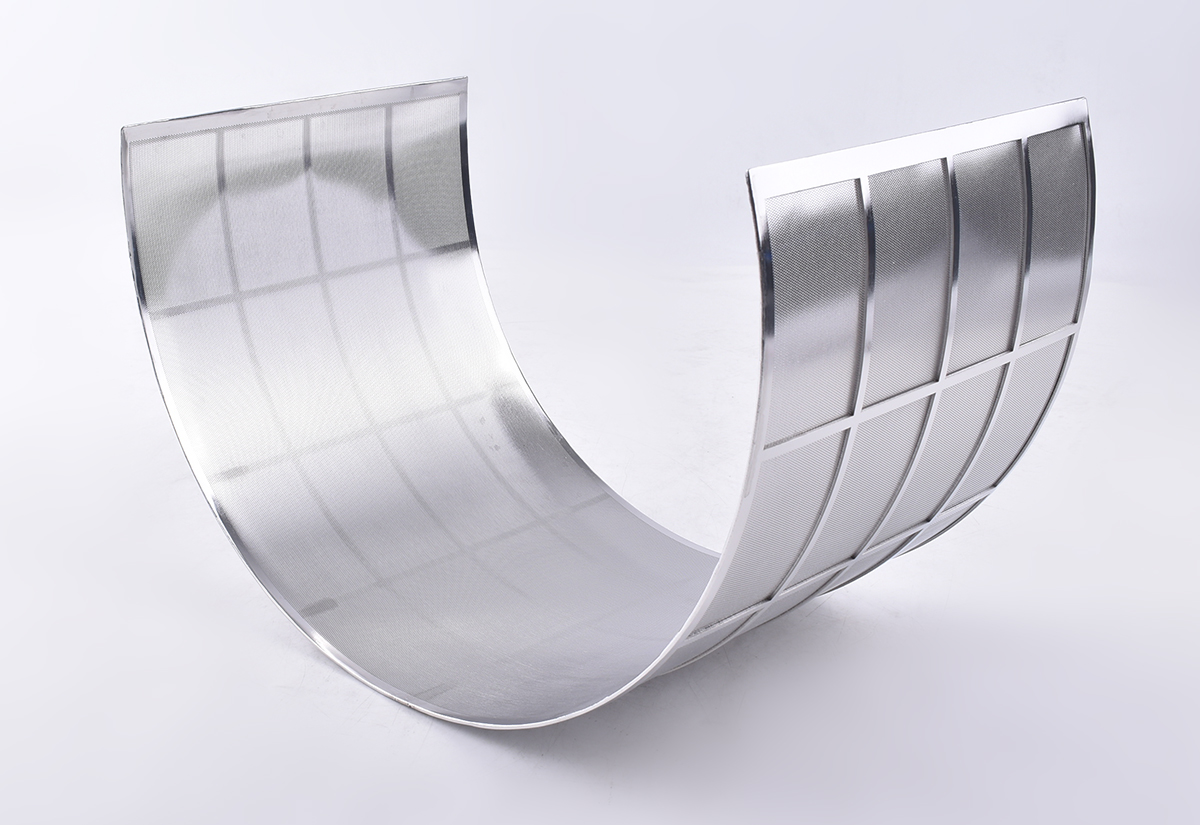

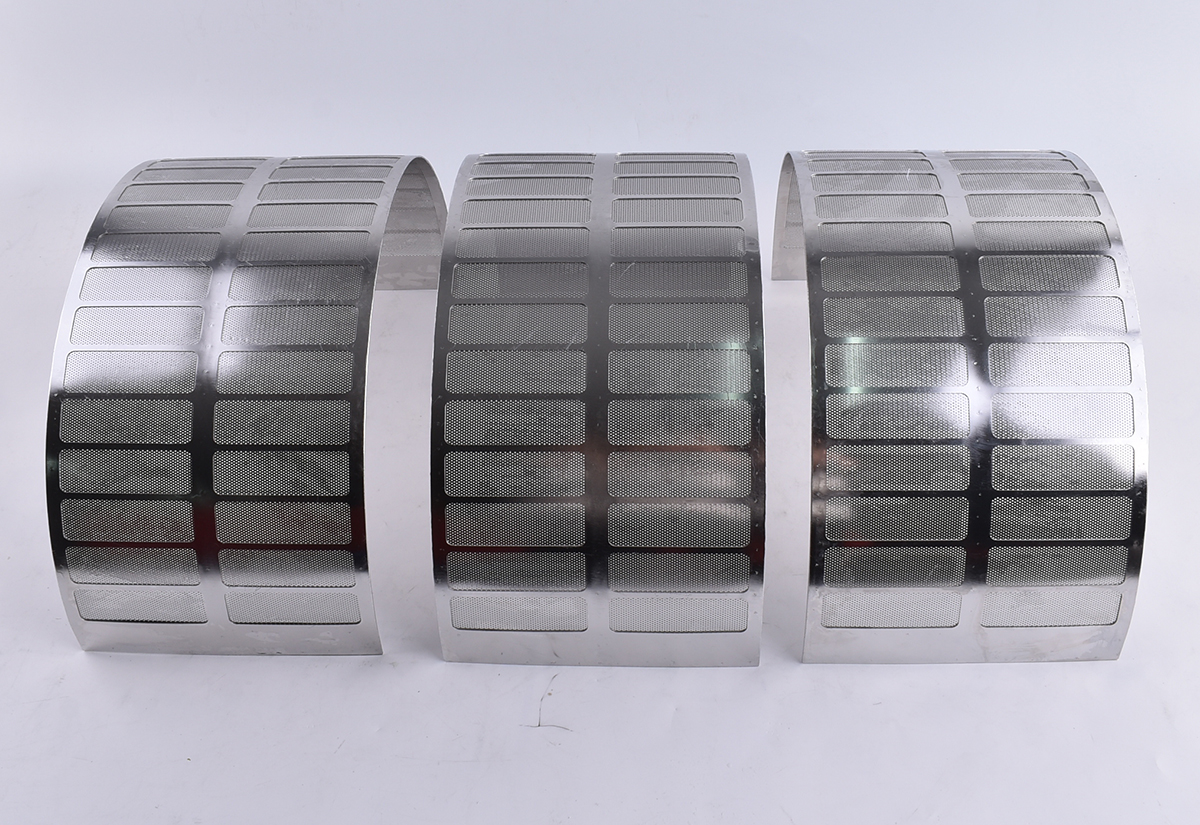

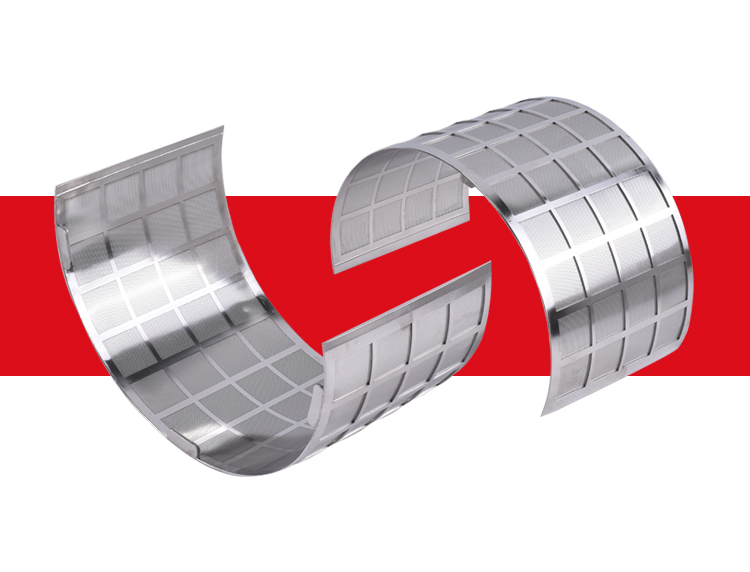

Stainless steel micro-porous arc-shaped screen mesh

Stainless steel micro-perforated arc-shaped screen is a type of screen commonly used in screening and classification equipment, which combines stainless steel material with an arc-shaped design. The screen bars and support bars, usually made of cold-rolled stainless steel, are continuously wound and contact welded by automated machine tools. The screen seams are uniform and the welding quality is stable. It has a high opening rate, which can increase the screening area, improve the screening efficiency, make the materials pass through the screen more easily, reduce the clogging phenomenon and improve the screening accuracy. The surface of the screen is arc-shaped, which can adapt to and protect the flow of materials. It is suitable for screening equipment of different specifications and models. The installation is relatively simple and the maintenance is also convenient.

Characteristics

- Strong corrosion resistance: Stainless steel material has excellent corrosion resistance and can be used for a long time in harsh environments such as dampness, acid and alkali. It is not prone to rust and is suitable for various complex working conditions.

- High strength: Made of steel, it has excellent mechanical properties, high strength and hardness, and can withstand greater pressure and impact, ensuring stability during the screening process.

- Good screening effect: The arc-shaped design increases the opening area of the screen plate, making the material pass through more smoothly, reducing blockage, improving screening accuracy and efficiency, and better achieving operations such as material classification, dewatering, and desliming.

- Good wear resistance: The surface is smooth, not prone to scaling, has excellent wear resistance, a long service life, can reduce replacement frequency and cut costs.

- Easy installation: It can be customized and installed according to actual needs, suitable for screening equipment of different specifications and models, and the operation is flexible.

Application

- In the mining field: It is used for screening and filtering of coal mines, gold mines, iron mines and other ores, for pre-dewatering, desliming and desmedia operations of ores, for the recovery of coal slime by classification, and can also be used in conjunction with water cyclones to effectively classify, dewater, desliming and desmedia fine-grained materials.

- Food processing industry: Screening, impurity removal and filtration are carried out on food raw materials such as flour, powdered sugar and grains to ensure the quality and purity of food.

- Chemical industry: Screening and grading of chemical raw materials, such as granular compounds, powders, granules and liquids, etc., to improve the quality of chemical products.

- Building materials industry: It is used for screening and filtering materials such as sand and gravel, cement, and glass to ensure that the quality and specifications of building materials meet the requirements.

- Other industries: In the steel industry, it is used for screening and impurity removal in the steel production process; It is used in the pharmaceutical industry for the screening and filtration of medicinal materials; It can also be used for garbage treatment. Through screening, useful substances in the garbage can be separated from the garbage, achieving resource reuse.

Related Products

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element

-

Stainless steel micro-porous arc-shaped screen mesh

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element

-

Stainless steel microporous filter element