- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

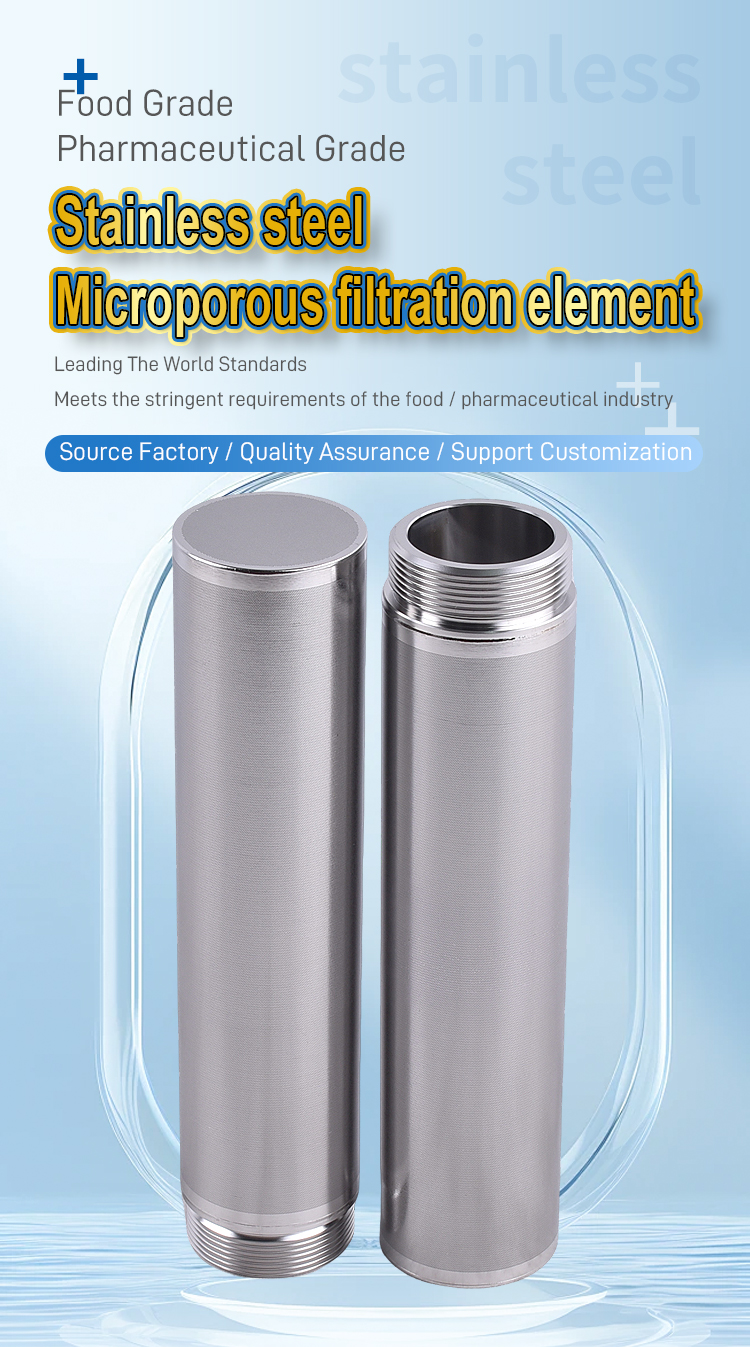

Stainless steel microporous filter element

The stainless steel microporous filter element is the core of the new type of filtration equipment, the microporous filter. It is of a folded cylindrical structure, made of special materials, with tiny pores. It is installed in a stainless steel housing, which is polished and complies with relevant standards. There are various connection methods.

Features

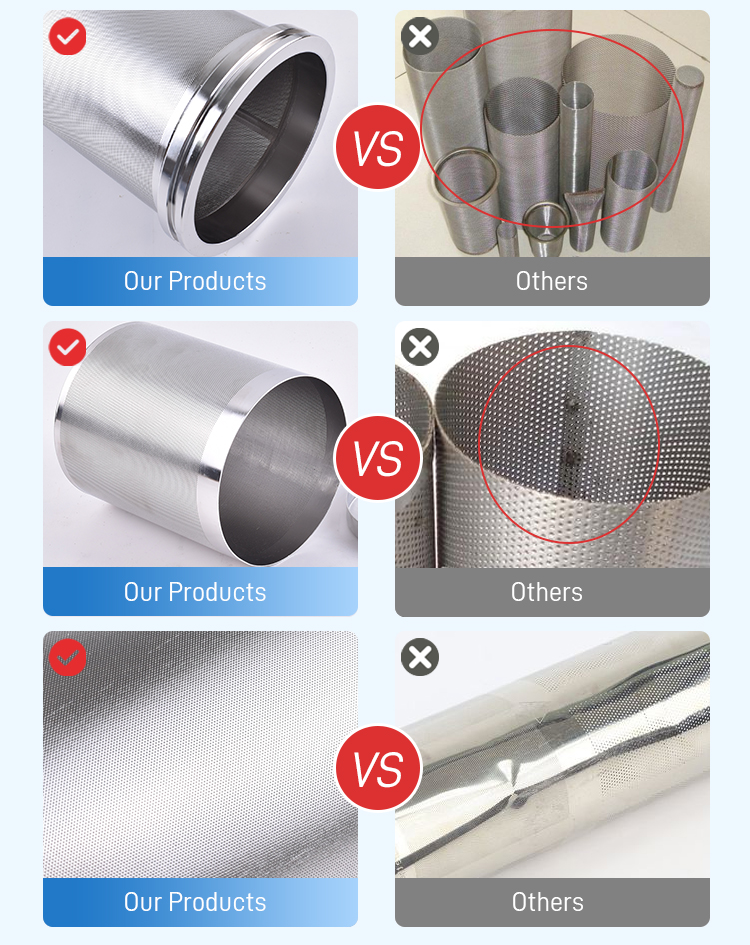

Outstanding filtration performance: It can retain particles and bacteria larger than 0.1μm, with a precision typically ranging from 0.1 to 100μm, commonly including 0.2μm, 0.45μm, 1μm, 5μm, etc., and features a fast filtration speed.

Adapt to harsh environments: Made of stainless steel, it is corrosion-resistant and heat-resistant, suitable for filtering in acidic and alkaline environments and highly viscous liquids.

Reusable: It can be cleaned and reused, reducing usage costs.

Good chemical compatibility: All-stainless steel structure, suitable for various chemical media.

Sturdy and durable structure: Some filter elements have a protective shell on the outer layer, and the internal support core can withstand high pressure. The top cone optimizes fluid dynamics performance to ensure structural stability.

Other features: The opening rate is as high as 30%, the maximum length is 6 meters, the outer diameter ranges from φ20mm to φ1250mm, and the gap (mm) is 0.02-0.5, which can be made according to customer requirements.

"Application

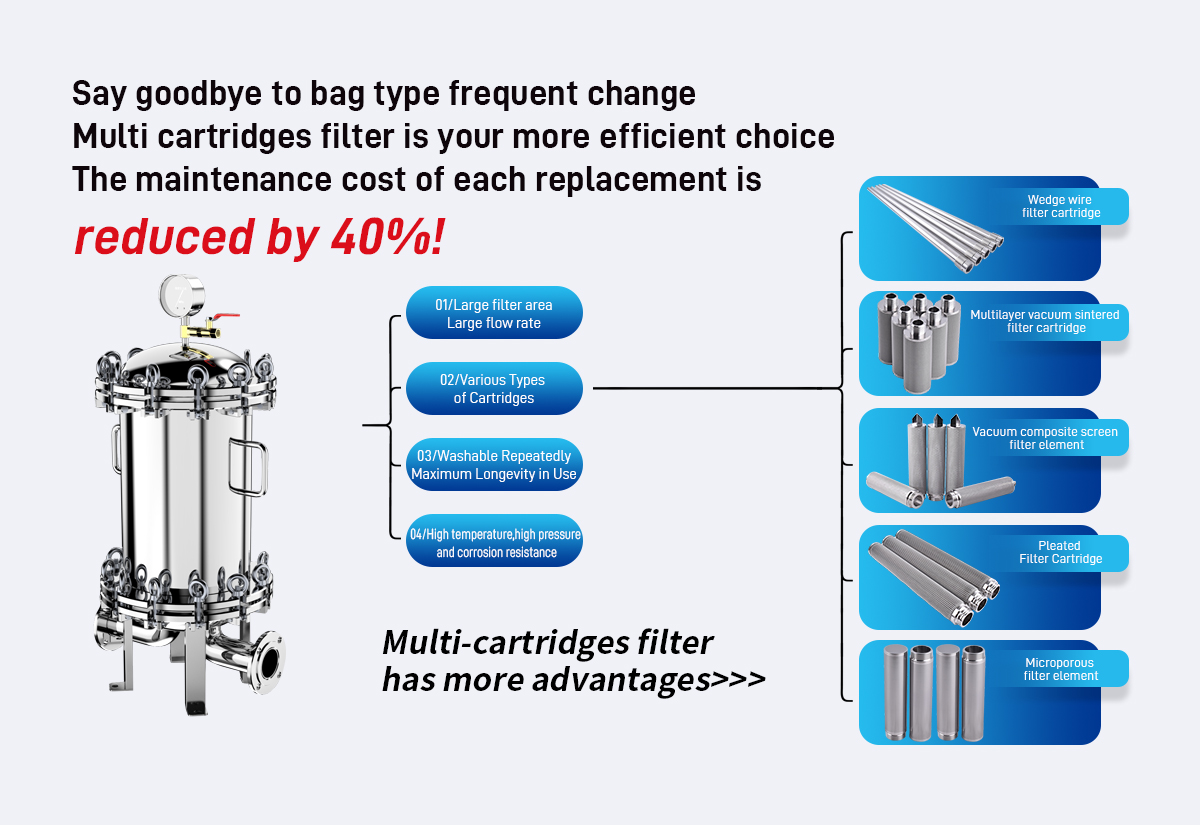

Pharmaceutical industry: It is used for sterilizing and filtering water for injection, liquid medicine, solvents, etc., to ensure a sterile environment during the drug production process.

Food and beverage industry: It is used in the production processes of fruit juice clarification, beer sterilization, mineral water filtration, wine, liquor, etc., to enhance product quality and taste.

In the field of environmental protection water treatment: It is used for wastewater treatment, waste gas purification, etc., to achieve resource recycling and environmental protection.

Other industries: It is also applied in the electronics industry, metallurgical industry, mechanical manufacturing and other industries.

Related Products

-

Multi-core filter

-

Stainless steel multi-bag filter

-

Online filter (external scraper

-

Dynamic self-cleaning filter

-

Stainless steel gas filter

-

Stainless steel respirator

-

Stainless steel Y-type angled filter

-

Stainless steel Y-type filter

-

Stainless steel Y-type filter

-

Straight-through pipe filter

-

Stainless steel magnetic filter

-

Stainless steel wedge-shaped wire filter element

-

Stainless steel pleated mesh filter element

-

Stainless steel microporous filter element

-

Stainless steel plate mesh filter element

-

Stainless steel composite mesh filter element