- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

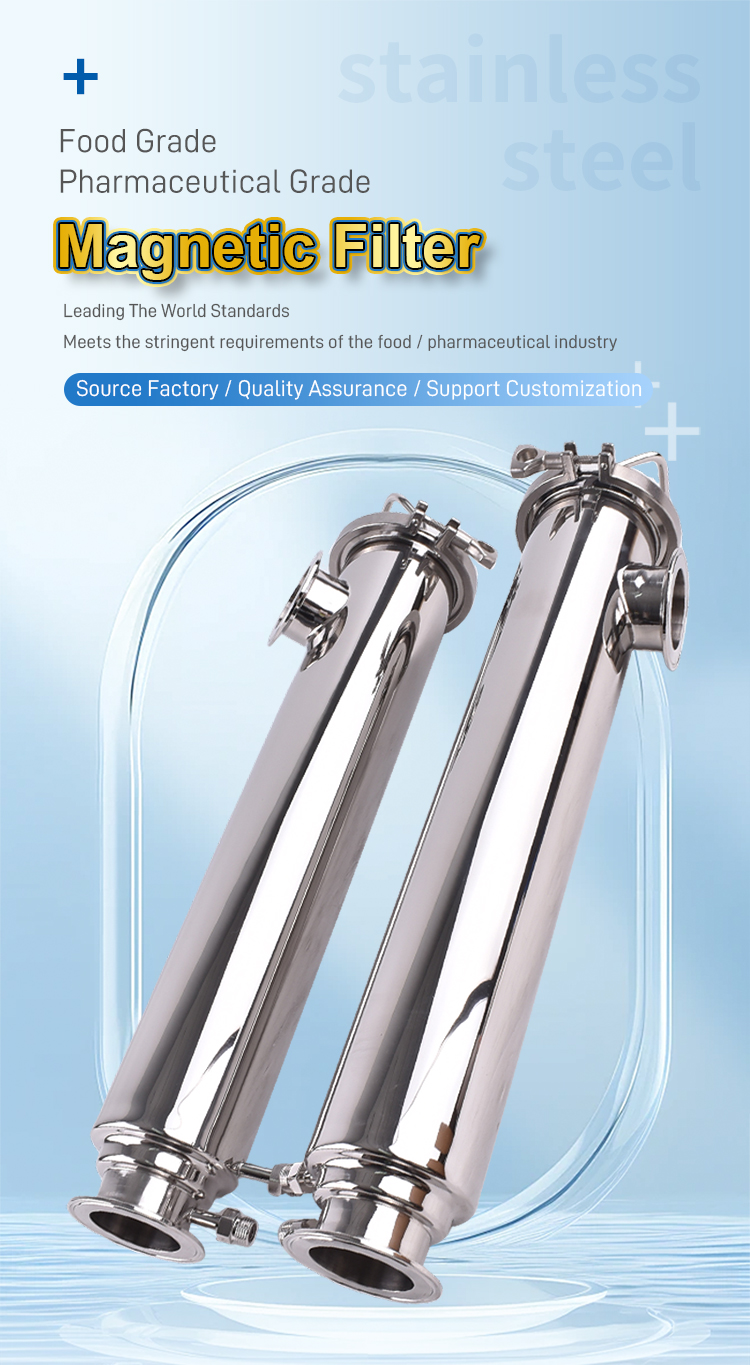

Stainless steel magnetic filter

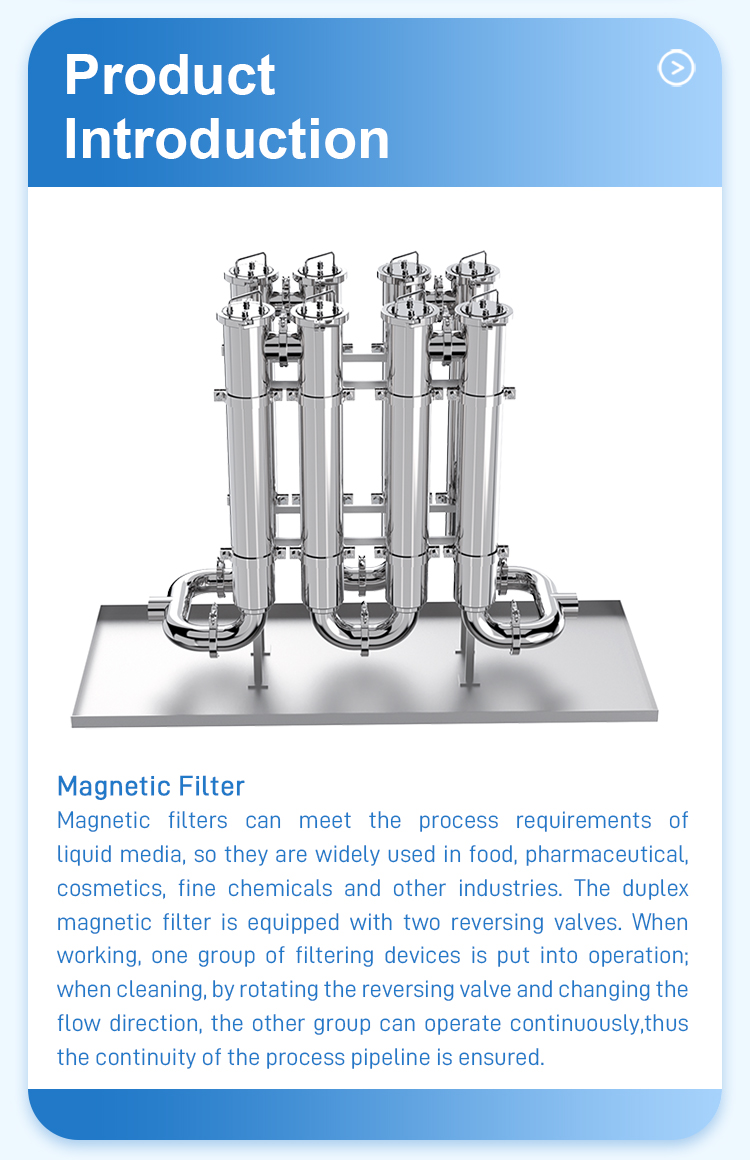

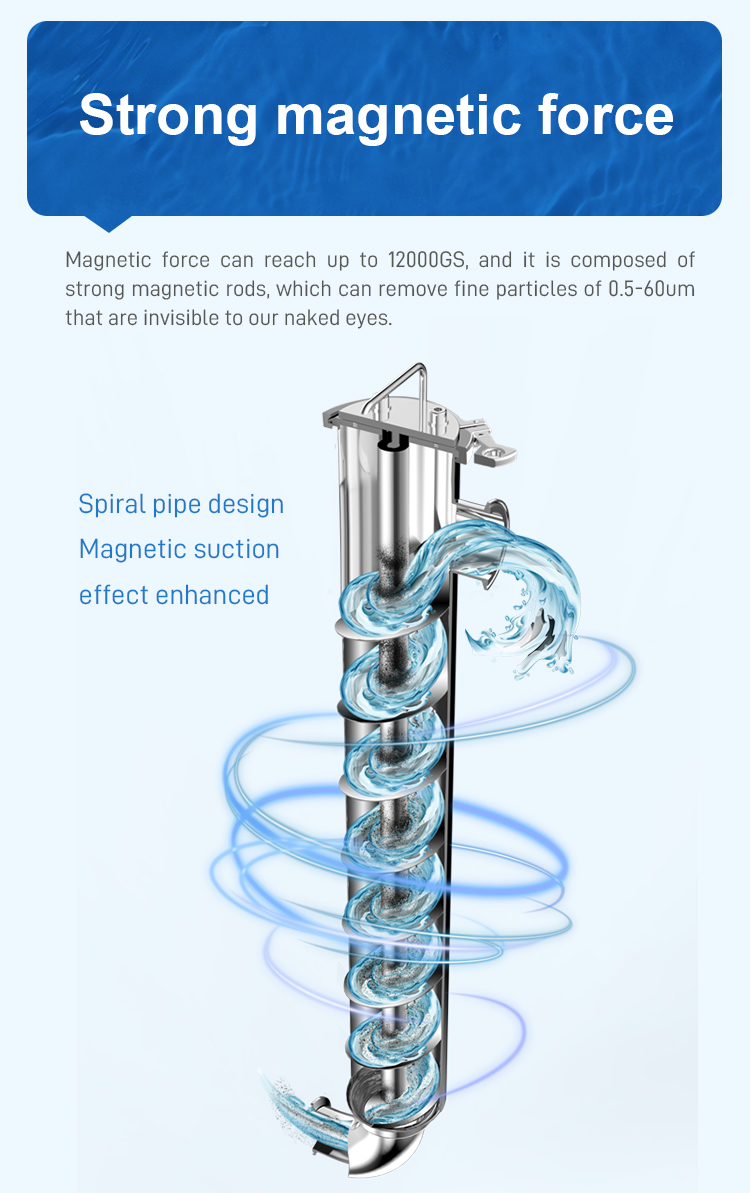

The stainless steel magnetic filter is composed of a magnetic rod group and a stainless steel cylinder. It uses the powerful magnetic field generated by the magnetic rods to filter out fine iron impurities in liquids, slurries, powders, gases and other materials conveyed by air pipelines. Common types include flange type, quick-installation type, etc.

Features

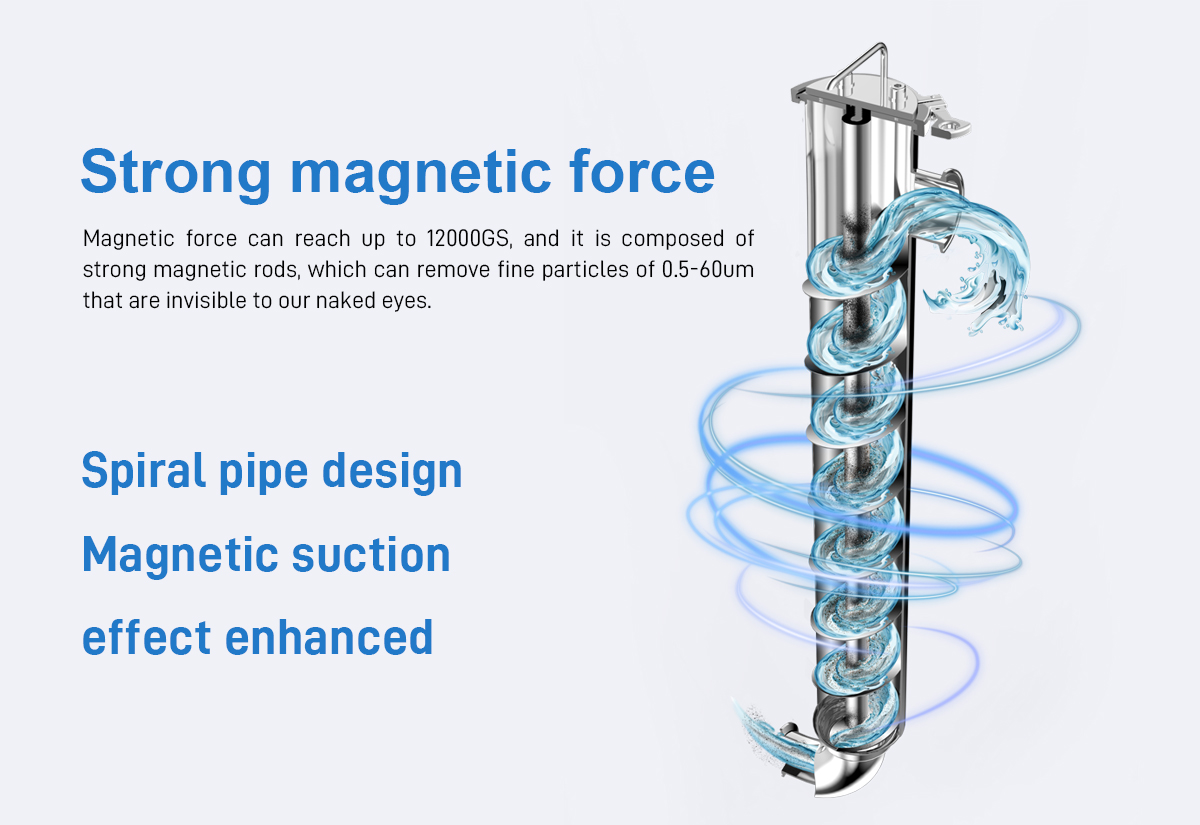

Strong magnetic force: The surface magnetic height can reach up to 10,000 Gs, and the magnetic force is 5 to 20 times higher than that of similar conventional magnetic materials (ferrite or alnico permanent magnetic materials). It has a good iron removal effect and can remove tiny particles ranging from 0.5 to 60μm that are difficult to see with the naked eye.

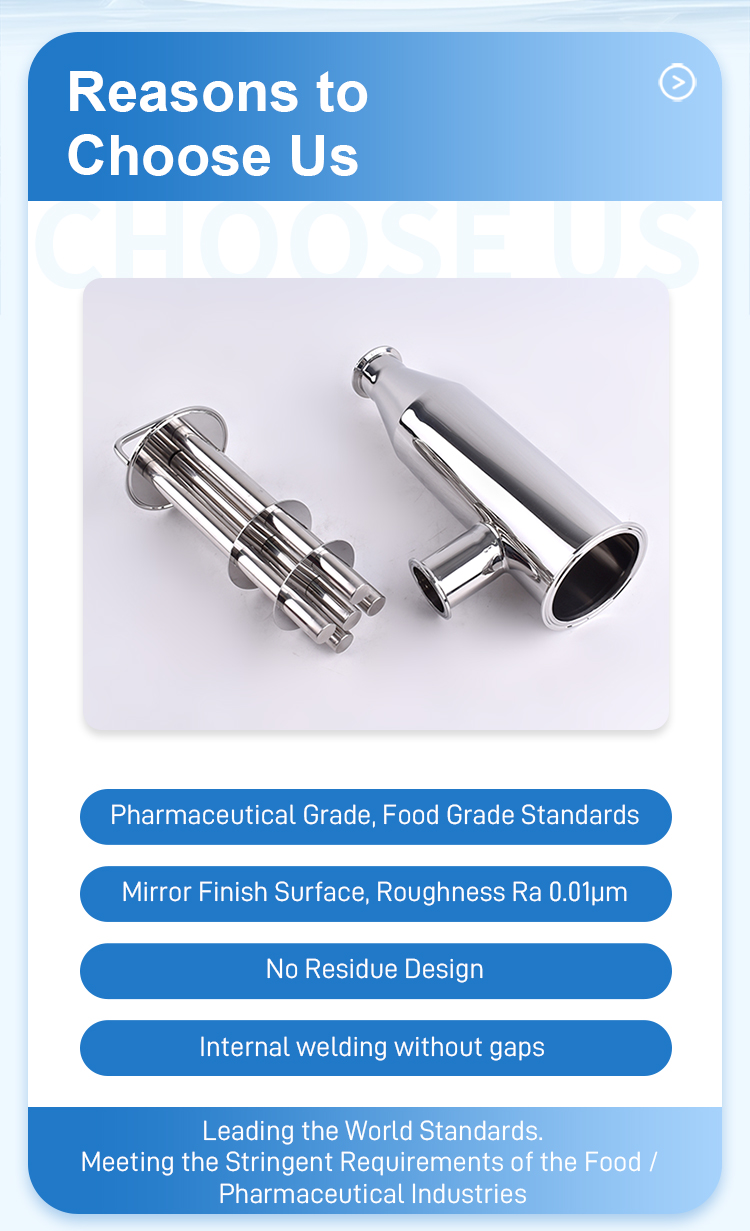

Material safety: High-quality stainless steel materials such as SS304 and SS316 are selected. Surface treatments include mirror polishing, brushed polishing, sandblasting, etc., which can meet food grade and hygiene grade standards. It is corrosion-resistant, has high strength and good toughness, and can adapt to various harsh working conditions, ensuring the long-term stable operation of the equipment.

Easy to clean: When cleaning, unscrew the drain plug at the bottom of the main pipe to drain the fluid, remove the flange cover, take out the filter screen or magnetic rod for cleaning, and then reinstall it for continued use. When cleaning some quick-installation filters, first loosen the clamping screws on the cover, remove the sleeve cover component, pull out the magnetic rod, and the adsorbed iron impurities will fall off automatically. After cleaning, reinstall the sleeve into the cylinder, tighten the clamping screws, and then insert the magnetic rod cover.

Low operating cost: It does not consume energy during operation, has no moving parts, a long service life, and extremely low magnetic force attenuation. For instance, the attenuation of some products is only 1% within 10 years.

"Application

It is widely applied in industries such as chemical engineering, pharmaceuticals, pigments, dyes, food, metallurgy, ceramics, petrochemicals, refrigeration, and plastics. It is used to separate the fine iron filings contained in liquid media, reduce the iron ion content in products, improve product quality, protect the accessories on equipment pipelines from wear and blockage, and ensure the normal operation of equipment.

Related Products

-

Multi-core filter

-

Stainless steel multi-bag filter

-

Online filter (external scraper

-

Dynamic self-cleaning filter

-

Stainless steel gas filter

-

Stainless steel respirator

-

Stainless steel Y-type angled filter

-

Stainless steel Y-type filter

-

Stainless steel Y-type filter

-

Straight-through pipe filter

-

Stainless steel magnetic filter

-

Stainless steel wedge-shaped wire filter element

-

Stainless steel pleated mesh filter element

-

Stainless steel microporous filter element

-

Stainless steel plate mesh filter element

-

Stainless steel composite mesh filter element