Equipment category

In the pharmaceutical industry, the production of active pharmaceutical ingredients involves various types of equipment

Reaction equipment

Commonly used for the synthesis of raw drugs include reaction towers, reaction vessels, pumps, tanks, etc. These devices provide the venue and conditions for chemical reactions. By controlling parameters such as temperature, pressure, and stirring speed, the raw materials undergo chemical reactions to generate the target products. For instance, in the production of chemically synthesized drugs, reaction vessels are commonly used equipment. They can withstand certain pressures and temperatures to ensure the smooth progress of the reaction.

Drying equipment

This includes ovens and fluidized bed dryers, etc., which are used to remove moisture from active pharmaceutical ingredients to ensure the stability of the product. The drying process can prevent the deterioration of active pharmaceutical ingredients during storage and use, and improve the quality of the drugs. For instance, fluidized bed dryers achieve uniform drying by suspending materials under the action of hot air flow, and they have the advantages of fast drying speed and good product quality.

Crystallization equipment

It is used to crystallize the solution of raw drugs to obtain high-purity crystals. The design and operating conditions of crystallization equipment have a significant impact on the quality and purity of crystals. Common crystallization equipment includes cooling crystallizers, evaporation crystallizers, etc. Different equipment is suitable for different active pharmaceutical ingredients and process requirements.

Extraction equipment

It is used to extract target components from mixtures. By taking advantage of the differences in solubility of different substances in solvents, the separation and enrichment of target components are achieved. Common extraction equipment includes liquid-liquid extraction towers, solid-liquid extractors, etc. In the pharmaceutical industry, extraction equipment is often used to extract the active ingredients from Chinese herbal medicines or purify raw materials.

Heat exchanger

It is used to achieve heat transfer, enabling the active pharmaceutical ingredient to maintain an appropriate temperature during the reaction process. Heat exchangers can enhance energy utilization efficiency and reduce energy consumption. Common types of heat exchangers include tube heat exchangers, plate heat exchangers, etc. They have different structures and characteristics and are suitable for different process conditions and fluid properties.

Storage device

It is used for storing active pharmaceutical ingredients and intermediates to ensure their quality and stability during the storage process. Storage devices usually have good sealing performance and functions such as moisture-proofing and mold-proofing. Common storage equipment includes storage tanks, warehouses, etc. For some special active pharmaceutical ingredients, special storage conditions also need to be adopted, such as low-temperature storage and light-proof storage.

Filtration and separation equipment

In addition to the filters mentioned earlier, it also includes centrifuges, etc. A centrifuge is a device that uses the centrifugal force generated by high-speed rotation to separate liquids from solid particles or liquids of different densities. It is widely used in laboratories, medicine, chemical engineering and other fields. It can be used for operations such as blood separation, cell culture, and sample purification. By taking advantage of the differences in sedimentation speeds of substances of different densities under the action of centrifugal force, it achieves the separation of substances.

Evaporation equipment

It is used to evaporate the solvent in the solution, thereby obtaining a concentrated solution or solid solute. Evaporation equipment is often used in the pharmaceutical industry for operations such as concentrating liquid medicine and recovering solvents. Common evaporation equipment includes single-effect evaporators, multi-effect evaporators, vacuum evaporators, etc. They achieve the concentration of solutions and the recovery of solvents through different evaporation principles and process flows.

Distillation equipment

A device that separates components in a liquid mixture by taking advantage of the differences in volatility among the components. In the pharmaceutical industry, distillation equipment can be used to separate and purify organic solvents, extract active ingredients, etc. For instance, molecular distillation equipment can carry out distillation under high vacuum and is suitable for the distillation separation of high-boiling-point, heat-sensitive and easily oxidized substances.

Screening machinery

It is used for screening and grading active pharmaceutical ingredients or intermediates to ensure uniform and consistent particle size of the products. There are various types of screening machinery, with common ones including woven screens and punched screens, etc. The mesh of the woven sieve is relatively dense, making it suitable for screening fine particles. The punched screen is more durable and is suitable for screening materials with larger particles.

Other equipment

It also includes homogenizers, etc. The homogenizer achieves refinement and homogenization of the material by subjecting it to powerful shearing, friction and high-frequency vibration through the gap between the high-speed rotating rotor and stator. In the pharmaceutical industry, homogenizers are often used to prepare vaccines, biological preparations, etc., to enhance the stability and quality of the products.

Zhehan offers filtration solutions for equipment in the pharmaceutical industry, helping you reduce production costs and improve product quality.

-

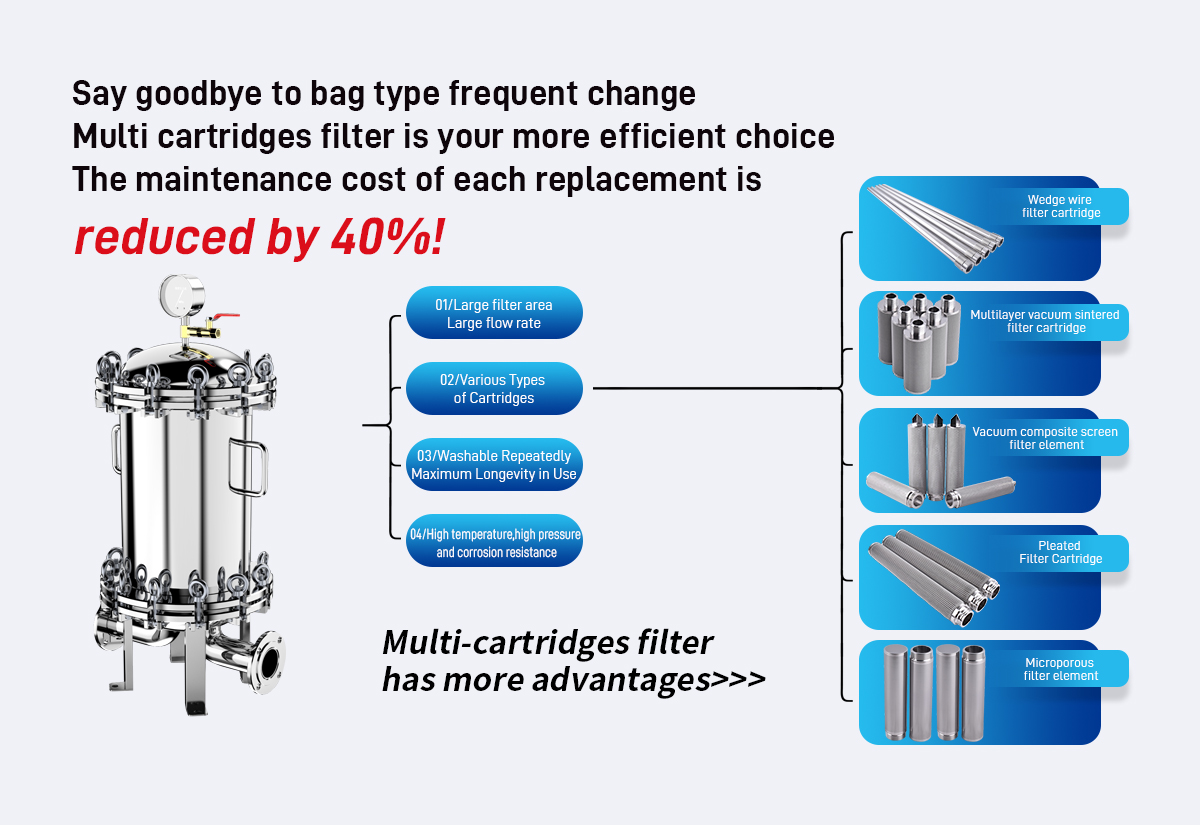

Multi-core filter

-

Stainless steel multi-bag filter

-

Online filter (external scraper

-

Dynamic self-cleaning filter

-

Stainless steel gas filter

-

Stainless steel respirator

-

Stainless steel Y-type angled filter

-

Stainless steel Y-type filter

-

Stainless steel Y-type filter

-

Straight-through pipe filter

-

Stainless steel magnetic filter

-

Stainless steel wedge-shaped wire filter element

-

Stainless steel pleated mesh filter element

-

Stainless steel microporous filter element

-

Stainless steel plate mesh filter element

-

Stainless steel composite mesh filter element