- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

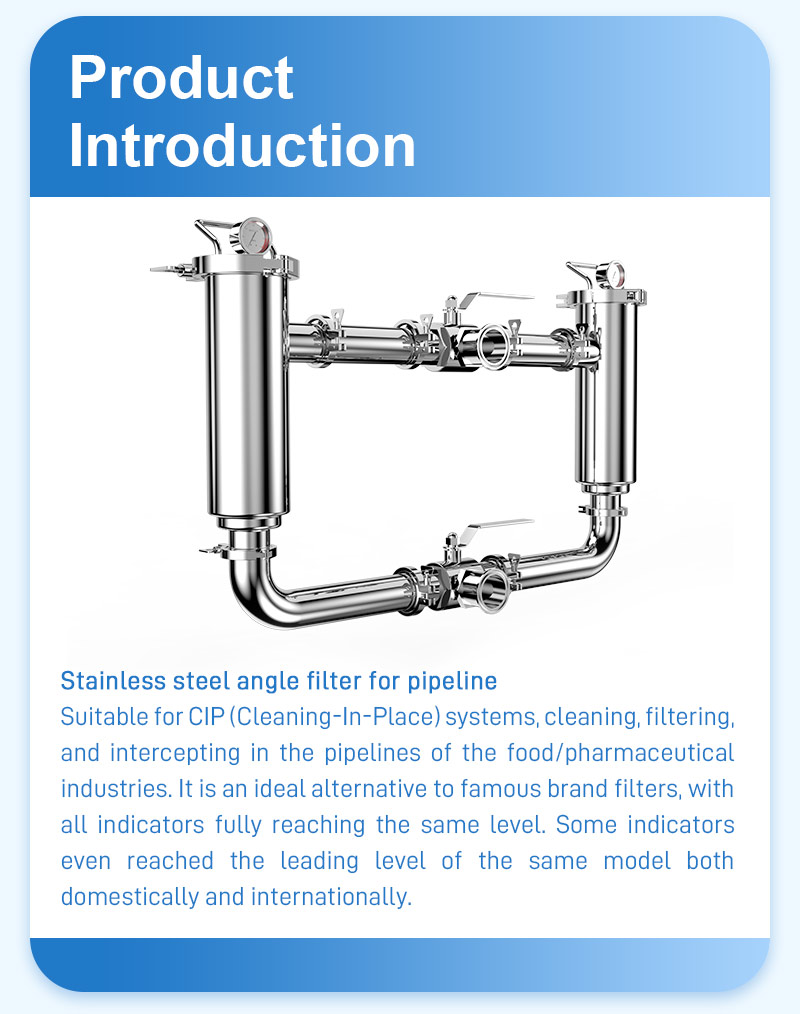

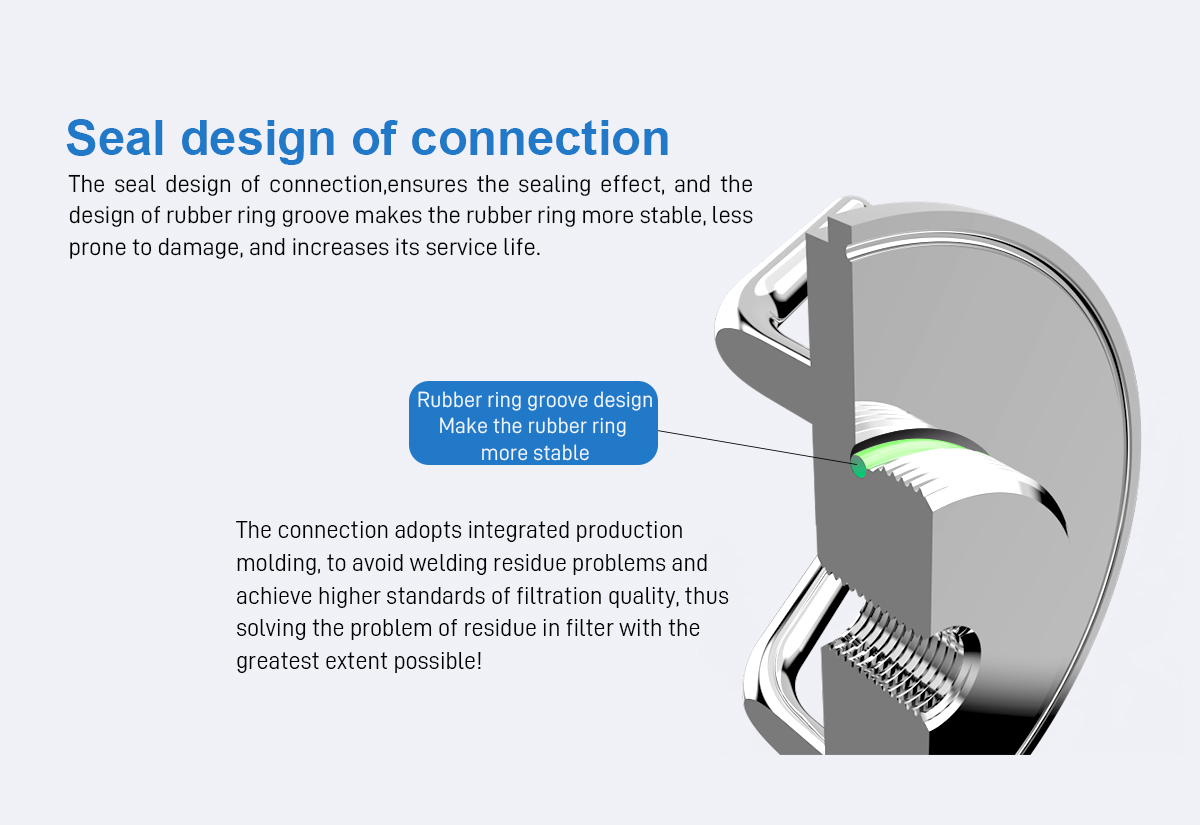

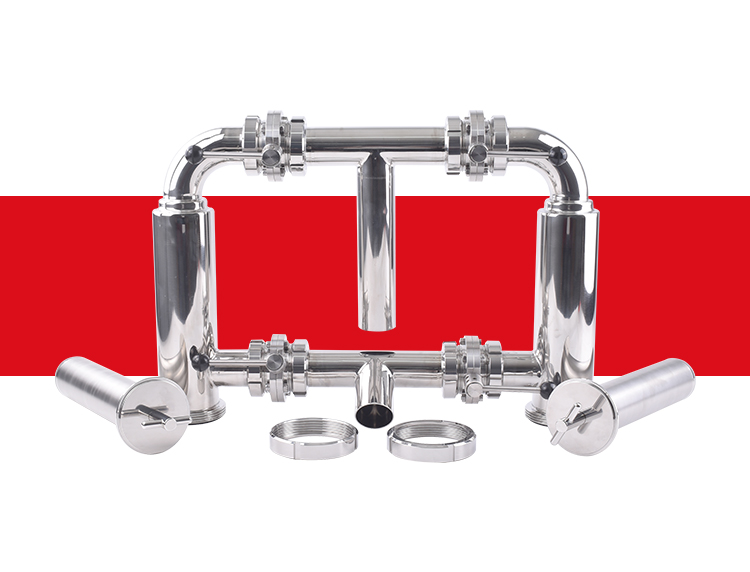

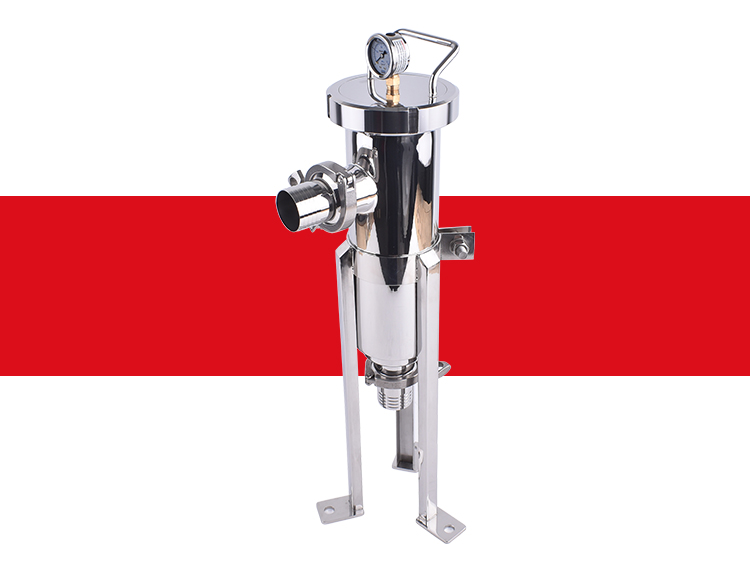

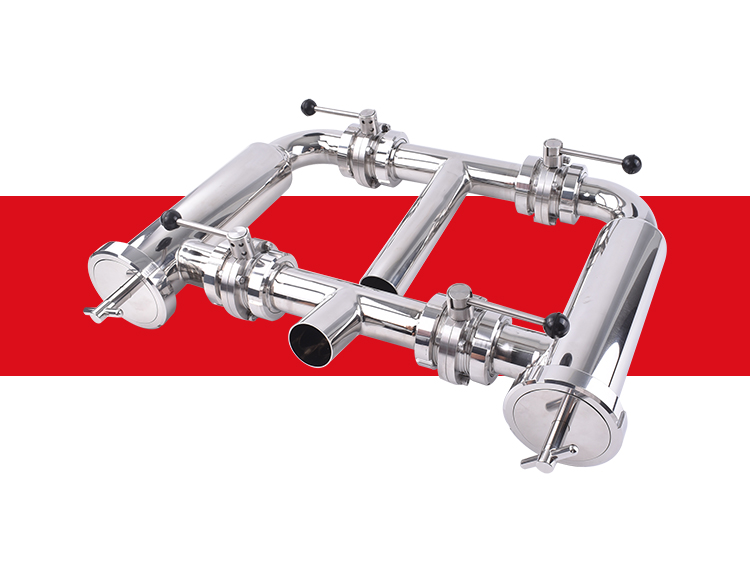

The stainless steel Angle filter is a device used to filter impurities in liquids. Its inlet and outlet are distributed at a 90° Angle. The main body is made of stainless steel and has structures such as filter elements inside. It belongs to the unit-type filtration equipment and is available in single and double types, capable of achieving liquid filtration and precision filtration.

Characteristics

Excellent filtration effect: Through the internal professional filter element screening, it can separate impurities and harmful substances, change the liquid flow direction to form turbulence, allowing impurities to fully contact the filter screen, and improve the filtration efficiency.

Reliable material: Made of stainless steel such as 304 and 316L, it is corrosion-resistant, has high strength and precision, can adapt to harsh working conditions, and ensures a long service life.

Simple operation and maintenance: Part of it is a quick-installation structure, allowing the filter element to be quickly disassembled and assembled for convenient cleaning and replacement. Some are also equipped with timed and differential pressure automatic drainage functions, reducing the difficulty and cost of maintenance.

Hygiene and environmental protection: The inner wall is smooth, not easy to breed bacteria, no chemical agents are added, and the chemical properties of the liquid are not changed, meeting GMP and FDA requirements.

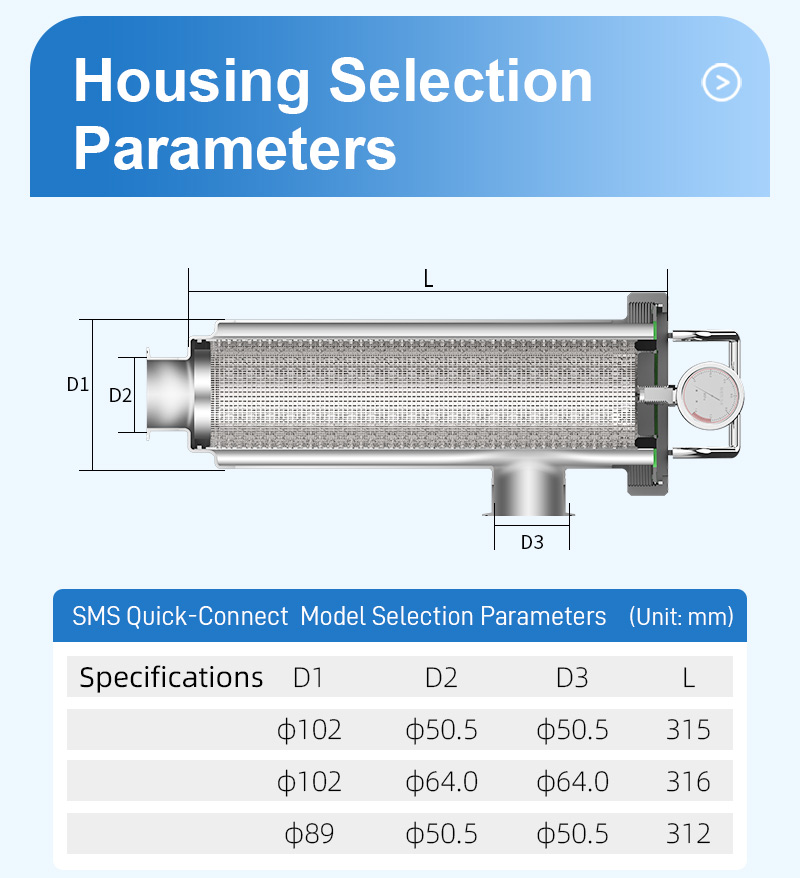

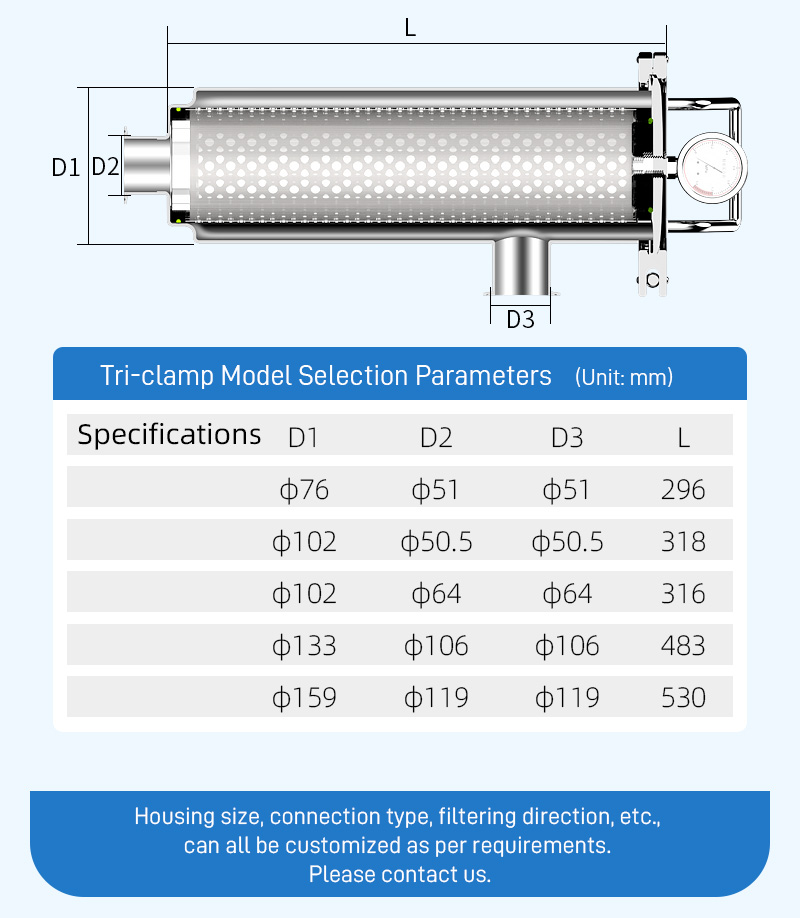

Wide precision range: The filtration precision can be selected between 25 microns and 5000 microns according to requirements.

Application

Food and beverage industry: It is used in the production processes of juice clarification, beer sterilization, mineral water filtration, wine, liquor, etc., to remove mechanical impurities in water, ensure product quality and taste, and meet hygiene standards.

In the pharmaceutical industry, during the production of active pharmaceutical ingredients, the preparation and filling of drug solutions, particulate impurities and microorganisms in raw materials and drug solutions are intercepted to ensure that the drugs are sterile and free of foreign substances, and comply with drug production standards.

In the chemical industry, during the transportation of chemical raw materials and the feeding of reaction vessels, impurities in acid and alkali solutions, organic solvents, etc. are filtered to protect equipment and improve product quality.

Environmental protection water treatment: It is used for industrial wastewater treatment, cooling water filtration, sewage purification, etc., to remove suspended solids, bacteria and other pollutants in water, and achieve resource recycling.

Other industries: It is applicable to water supply systems or fluid treatment in industries such as steel and metallurgy, papermaking, plastics, irrigation, shipping, and automobile manufacturing, ensuring the safe operation of equipment.