- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

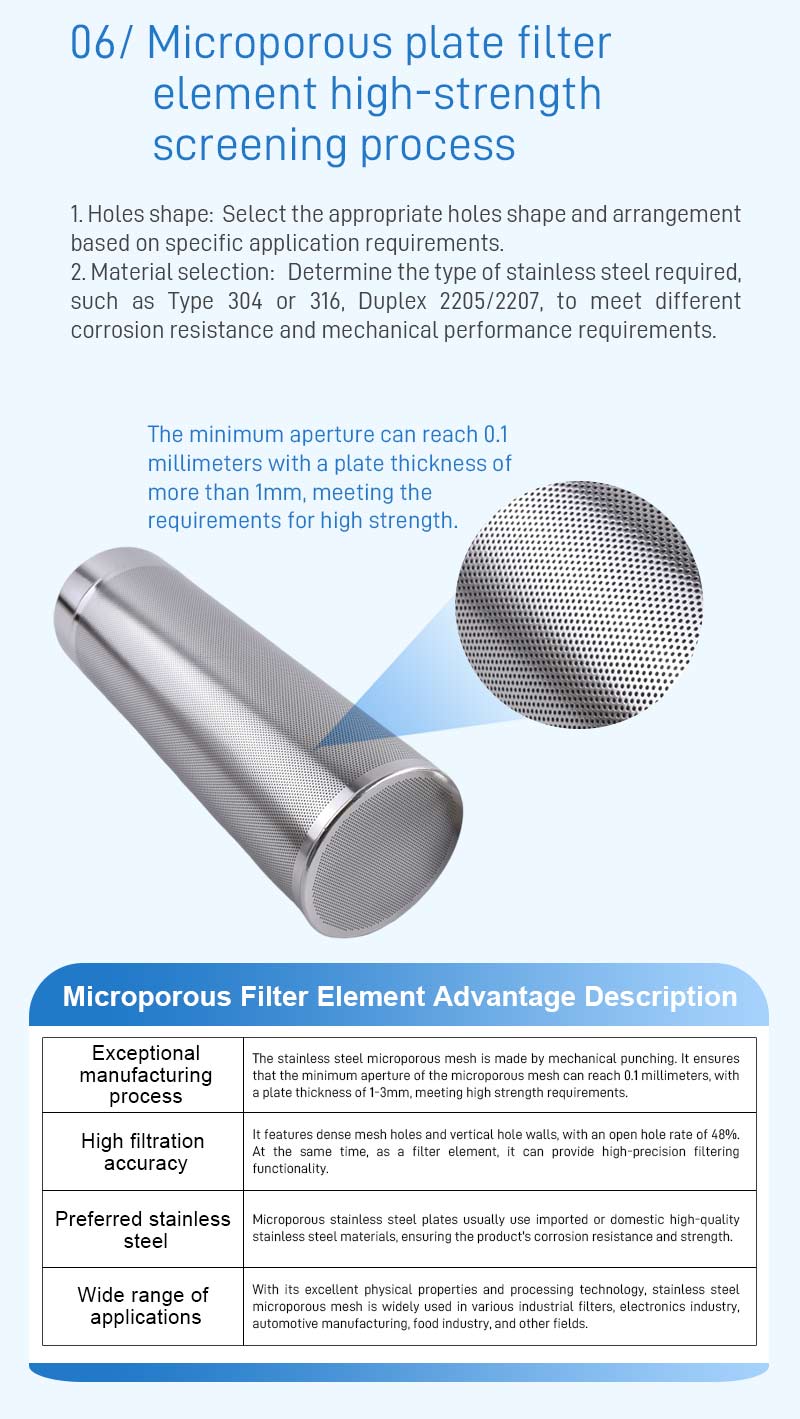

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

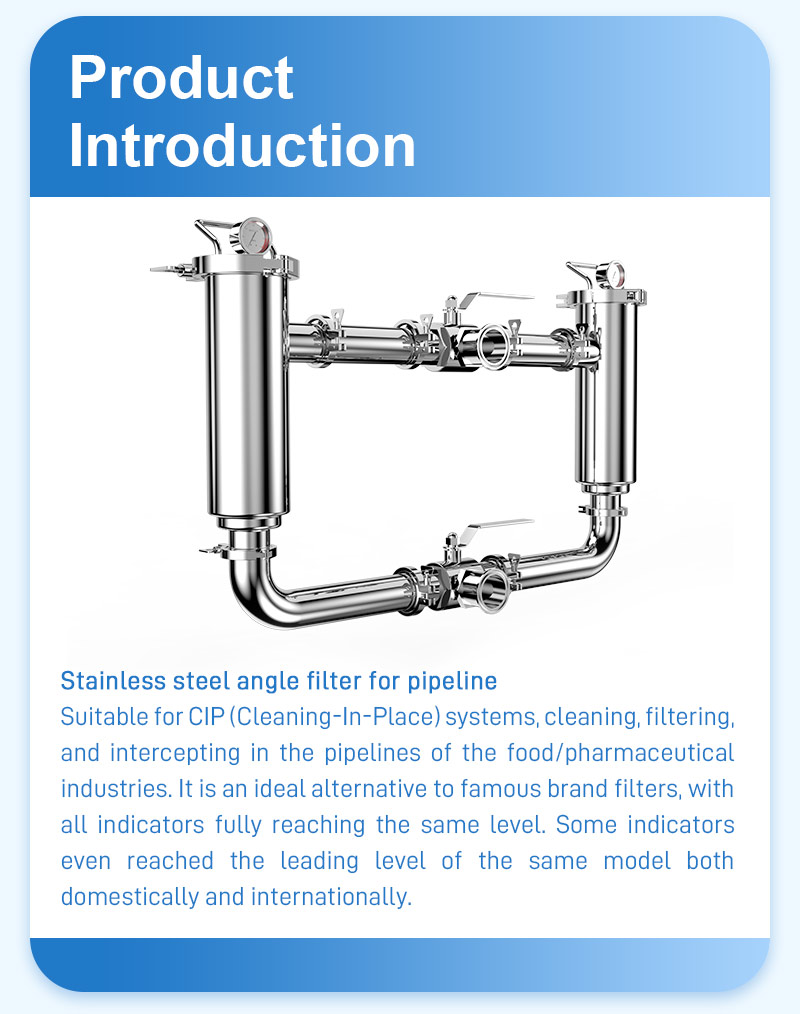

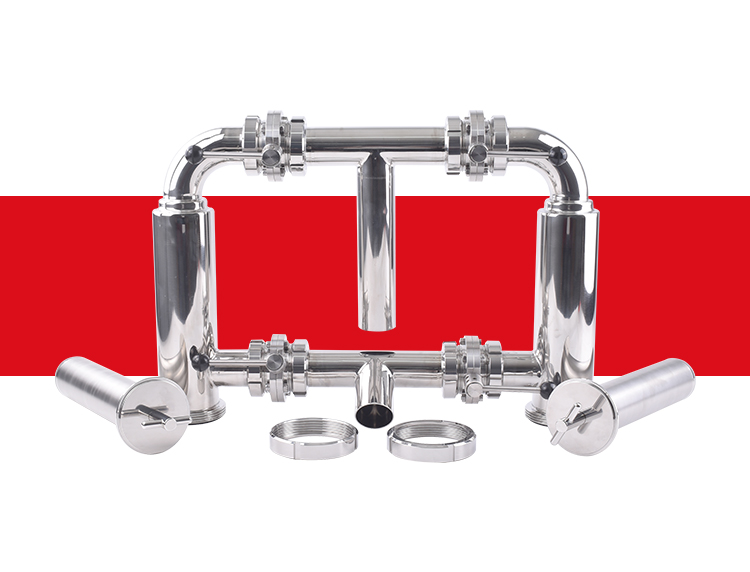

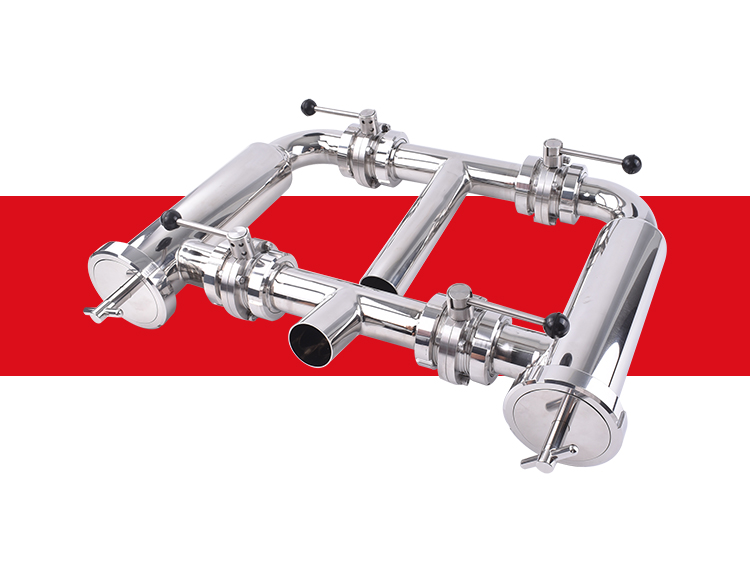

The double-angle filter is composed of two L-shaped Angle filter units connected in parallel. Each unit has fluid inlet and outlet at both ends, and a filter screen installation chamber is set at the corner. The bottom conical dirt collection chamber is inclined at 15°, which is conducive to the deposition and discharge of impurities. The inlet and outlet liquid main pipes are connected to the two units, and a switching valve group is equipped in the middle.

Characteristics

Alternating operation: The two filtration units can be used alternately. When the filter screen of one unit is clogged and needs to be cleaned, it can be quickly switched to the other unit to ensure continuous fluid delivery.

Right-angle structure: The right-angle structure turns the fluid towards the filter, and impurities settle naturally.

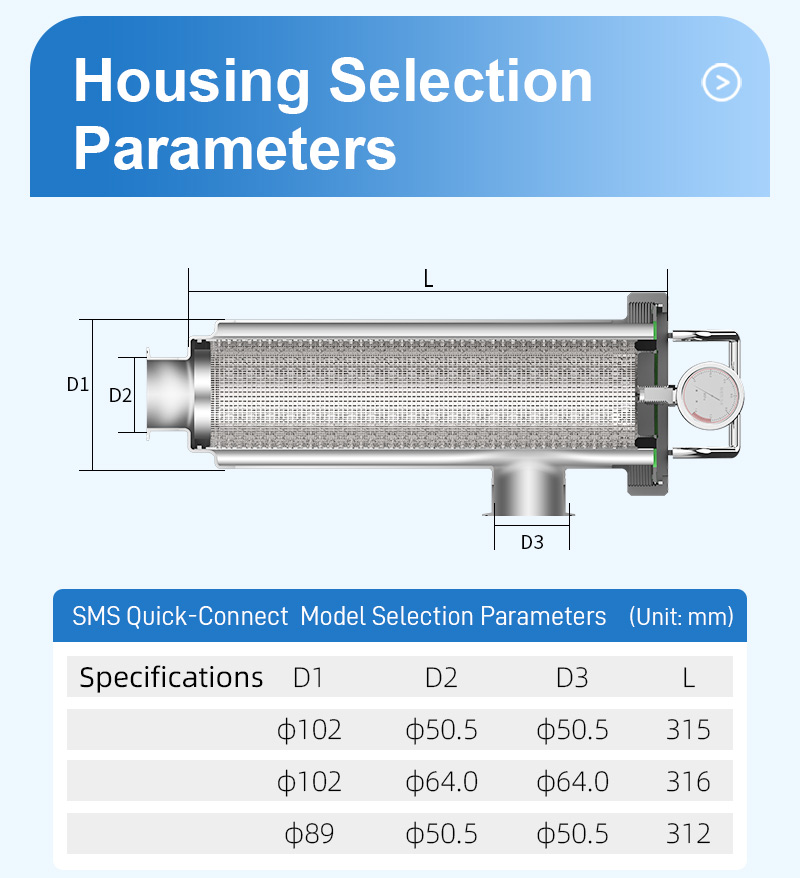

Diverse filtration accuracy: With filtration accuracy ranging from 10 to 300 mesh or 0.5 to 50 microns, it is suitable for various media such as water, oil, and gas.

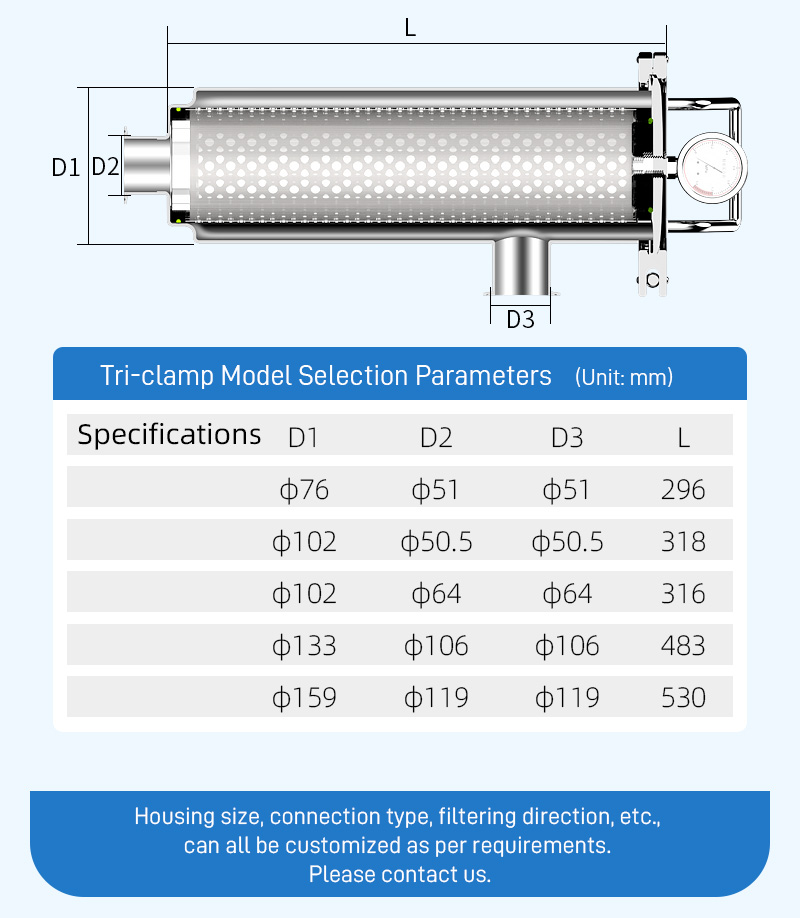

Diverse materials: The main body is made of stainless steel 304/316 or carbon steel (with surface anti-corrosion treatment), which can adapt to different working conditions.

Easy to maintain: The filter screen is fixed by a flange, which is convenient for disassembly and installation, and easy to clean and replace.

Application

Water treatment: It is used in municipal water supply, industrial circulating water, sewage treatment, etc., to remove impurities such as sand, rust and suspended solids from water.

In the chemical industry, during the transportation of chemical raw materials and the recovery of catalysts, impurities such as acid and alkali solutions, organic solvents, and catalyst particles are filtered to protect equipment.

Hvac: In the central air conditioning circulating water system and floor heating pipes, it filters impurities such as algae and sediment in the water to prevent equipment blockage.

Food and beverage industry: Filter pulp residues, foreign substances, etc. in production water, syrup, fruit juice and other fluids to ensure product quality.

Other industries: It is also applicable to fields such as petroleum, pharmaceuticals, light industry, food, papermaking, glue factories, electronics industry, waterworks, electroplating plants, laboratories, etc.